In the rapidly evolving world of lighting technology, LED linear lenses have emerged as a critical component in enhancing the performance and efficiency of lighting systems. The selection of materials used in the manufacturing of these lenses plays a pivotal role in determining their quality, durability, and overall effectiveness. This article explores the significance of material selection in LED linear lens manufacturing, the various factors that influence quality, and the implications for suppliers and manufacturers in the industry.

Understanding LED Linear Lenses

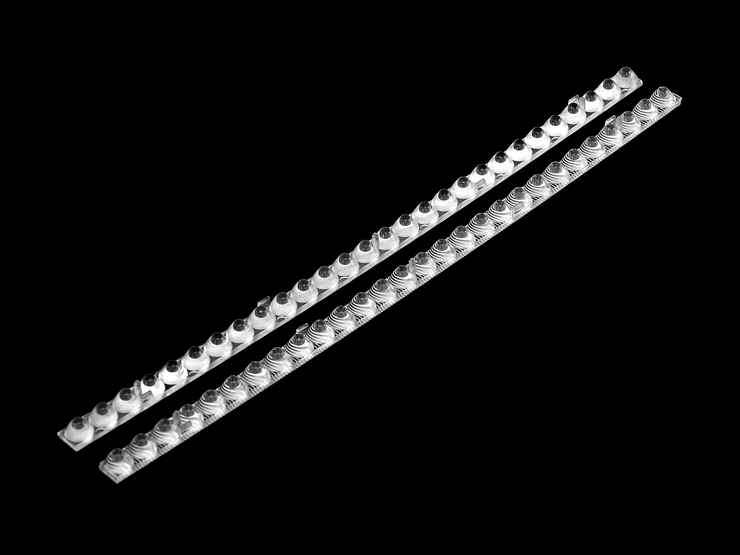

LED linear lenses are optical components designed to manipulate light emitted from LED sources. They serve various purposes, including controlling light distribution, reducing glare, and enhancing color rendering. The effectiveness of these lenses directly impacts the performance of LED lighting systems, making their quality paramount.

LED linear lenses are not just simple transparent covers; they are sophisticated optical devices that can significantly alter the way light interacts with surfaces and spaces. By utilizing advanced optical designs, these lenses can focus, diffuse, or direct light in specific patterns, which is essential for applications ranging from residential lighting to complex commercial installations. The design and material of the lens can also influence the aesthetic appeal of the lighting fixture, making it an important consideration for designers and architects.

The Role of Material Selection

Material selection is a fundamental aspect of LED linear lens manufacturing. The choice of materials affects not only the optical properties of the lenses but also their mechanical strength, thermal stability, and resistance to environmental factors. Common materials used in the production of LED linear lenses include:

- Acrylic (PMMA): Known for its excellent optical clarity and UV resistance, acrylic is a popular choice for LED lenses. It is lightweight and can be easily molded into various shapes, making it versatile for different applications. Acrylic lenses are often used in indoor lighting solutions where clarity and light transmission are critical.

- Polycarbonate (PC): This material offers superior impact resistance and thermal stability compared to acrylic. Polycarbonate lenses are ideal for applications where durability is essential, such as in outdoor lighting fixtures. Their ability to withstand harsh weather conditions and physical impacts makes them a preferred choice for street lighting and industrial applications.

- Glass: While heavier and more fragile than plastic options, glass lenses provide exceptional optical performance and scratch resistance. They are often used in high-end lighting applications where clarity and durability are critical. Glass lenses can also be treated with coatings to enhance their performance, such as anti-reflective coatings that improve light transmission.

The choice of material not only affects the lens's performance but also its cost and manufacturing process. Each material has its own set of advantages and disadvantages, which must be carefully considered based on the specific application and environmental conditions.

Key Factors Influencing Quality

When evaluating LED linear lens suppliers, several key factors should be considered to ensure high-quality products:

1. Optical Performance

The primary function of LED linear lenses is to optimize light output. High-quality lenses should provide uniform light distribution, minimize glare, and enhance color rendering. Suppliers should offer lenses that meet industry standards for optical performance. This includes testing for light transmission efficiency, color accuracy, and the ability to maintain consistent performance over time.

Optical performance is not just about how the lens looks; it directly affects the user experience. For instance, in a retail environment, the right lens can enhance product visibility and appeal, while in an office setting, it can reduce eye strain and improve comfort. Therefore, understanding the optical characteristics of different lens materials is crucial for achieving the desired lighting effects.

2. Manufacturing Capabilities

The manufacturing process significantly influences the quality of LED linear lenses. Suppliers should have advanced manufacturing capabilities, including precision molding and quality control measures. This ensures that each lens produced meets the required specifications and performance standards.

Modern manufacturing techniques, such as injection molding and CNC machining, allow for high precision and repeatability in lens production. Additionally, suppliers should implement rigorous quality assurance protocols, including testing for dimensional accuracy and optical performance, to ensure that every batch of lenses meets the highest standards.

3. Customization Options

Different applications require different lens designs. A reputable LED linear lens supplier should offer customization options to meet specific project needs. This includes variations in shape, size, and optical properties.

Customization can also extend to the surface finish of the lenses, such as frosted or clear options, which can affect light diffusion and glare reduction. By working closely with suppliers, manufacturers can develop tailored solutions that meet the unique requirements of their projects, enhancing both functionality and aesthetics.

4. Compliance with Standards

Quality assurance is crucial in the manufacturing of LED linear lenses. Suppliers should comply with relevant industry standards, such as ISO certifications and RoHS compliance, to ensure that their products are safe and reliable.

Compliance with these standards not only ensures product quality but also builds trust with customers. Manufacturers should seek suppliers who are transparent about their compliance processes and can provide documentation to verify their adherence to industry regulations.

5. Environmental Considerations

Sustainability is becoming increasingly important in the lighting industry. Suppliers should consider the environmental impact of their materials and manufacturing processes. Using recyclable materials and minimizing waste can enhance a supplier's reputation and appeal to environmentally conscious customers.

Incorporating sustainable practices can also lead to cost savings in the long run. For example, using materials that are easier to recycle can reduce disposal costs and improve the overall lifecycle of the product. As consumers become more aware of environmental issues, manufacturers that prioritize sustainability will likely gain a competitive edge in the market.

The Impact of Quality on Performance

The quality of LED linear lenses directly affects the performance of lighting systems. High-quality lenses can enhance energy efficiency, improve light distribution, and extend the lifespan of LED fixtures. Conversely, poor-quality lenses can lead to issues such as uneven lighting, increased glare, and reduced overall effectiveness.

For instance, a well-designed lens can help to focus light more effectively, reducing the amount of energy wasted and improving the overall efficiency of the lighting system. This not only lowers energy costs but also contributes to a more sustainable lighting solution. Additionally, high-quality lenses are less likely to degrade over time, ensuring that the lighting performance remains consistent throughout the lifespan of the fixture.

Case Studies: Quality in Action

To illustrate the importance of material selection and manufacturing quality, consider the following case studies:

Case Study 1: Commercial Lighting

In a recent project for a commercial office space, a leading LED linear lens supplier provided high-quality acrylic lenses that optimized light distribution. The result was a well-lit environment that enhanced productivity and reduced energy costs. The lenses' durability also ensured a long lifespan, minimizing maintenance needs.

The project highlighted how the right lens choice can transform a workspace. Employees reported increased comfort and satisfaction due to the improved lighting conditions, which in turn boosted overall productivity. This case underscores the importance of selecting a reputable LED linear lens supplier who can deliver high-quality products tailored to specific needs.

Case Study 2: Outdoor Lighting

A city municipality sought to upgrade its street lighting system. By selecting polycarbonate lenses from a reputable supplier, they achieved a significant reduction in vandalism due to the lenses' impact resistance. Additionally, the lenses provided excellent thermal stability, ensuring consistent performance in varying weather conditions.

This upgrade not only improved safety in the area but also enhanced the aesthetic appeal of the streets. The municipality received positive feedback from residents, demonstrating how quality materials can lead to better community outcomes. This case illustrates the broader implications of material selection beyond just functionality, impacting public perception and satisfaction.

Choosing the Right LED Linear Lens Supplier

Selecting the right supplier is crucial for achieving high-quality LED linear lenses. Here are some tips for making an informed choice:

1. Research and Reviews: Look for suppliers with a proven track record in the industry. Customer reviews and case studies can provide insights into their reliability and product quality.

2. Request Samples: Before making a bulk purchase, request samples to evaluate the optical performance and material quality of the lenses. This hands-on approach allows manufacturers to assess the suitability of the lenses for their specific applications.

3. Assess Technical Support: A good supplier should offer technical support and guidance throughout the selection and installation process. This can be invaluable, especially for complex projects that require precise specifications.

4. Evaluate Customization Capabilities: Ensure that the supplier can meet your specific design and performance requirements. A supplier that offers a range of customization options can help you achieve the desired lighting effects.

5. Check Compliance and Certifications: Verify that the supplier adheres to industry standards and regulations, ensuring the safety and reliability of their products. This step is crucial for maintaining quality and building trust with customers.

Conclusion

Material selection is a critical factor in the manufacturing quality of LED linear lenses. By understanding the importance of materials, evaluating key quality factors, and choosing the right suppliers, manufacturers can significantly enhance the performance and reliability of their lighting systems. As the demand for efficient and effective lighting solutions continues to grow, the role of high-quality LED linear lenses will remain paramount in the industry.

Frequently Asked Questions

1. What materials are commonly used for LED linear lenses?

- Common materials include acrylic (PMMA), polycarbonate (PC), and glass, each offering different optical and mechanical properties.

2. How does lens quality affect LED lighting performance?

- High-quality lenses improve light distribution, reduce glare, and enhance color rendering, leading to better overall lighting performance.

3. What should I look for in an LED linear lens supplier?

- Look for suppliers with a proven track record, customization options, compliance with industry standards, and strong technical support.

4. Why is sustainability important in lens manufacturing?

- Sustainable practices reduce environmental impact and appeal to customers who prioritize eco-friendly products.

5. Can I customize LED linear lenses for specific applications?

- Yes, many suppliers offer customization options to meet specific design and performance requirements.