Custom CNC milling has become a cornerstone of modern manufacturing, offering unparalleled precision and flexibility for a wide range of applications. This article delves into the various aspects of custom CNC milling services, exploring why they are an excellent choice for your next project.

Understanding CNC Milling

CNC milling, or Computer Numerical Control milling, is a subtractive manufacturing process that utilizes computer-controlled machines to remove material from a workpiece. This process allows for the creation of complex shapes and designs with high accuracy. The evolution of CNC technology has transformed traditional machining methods, enabling manufacturers to achieve levels of precision that were previously unattainable.

The CNC Milling Process

The CNC milling process involves several key steps:

Design Creation: The first step is to create a digital design using CAD (Computer-Aided Design) software. This design serves as the blueprint for the milling process. CAD software allows designers to visualize their ideas in a three-dimensional space, making it easier to identify potential issues before production begins.

Programming the CNC Machine: Once the design is complete, it is converted into a format that the CNC machine can understand. This involves generating a G-code, which instructs the machine on how to move and operate. The programming phase is critical, as it determines the efficiency and accuracy of the milling process.

Material Setup: The chosen material is securely fixed to the machine's worktable. This could be metal, plastic, wood, or other materials suitable for milling. Proper setup is essential to prevent any movement during the milling process, which could lead to inaccuracies.

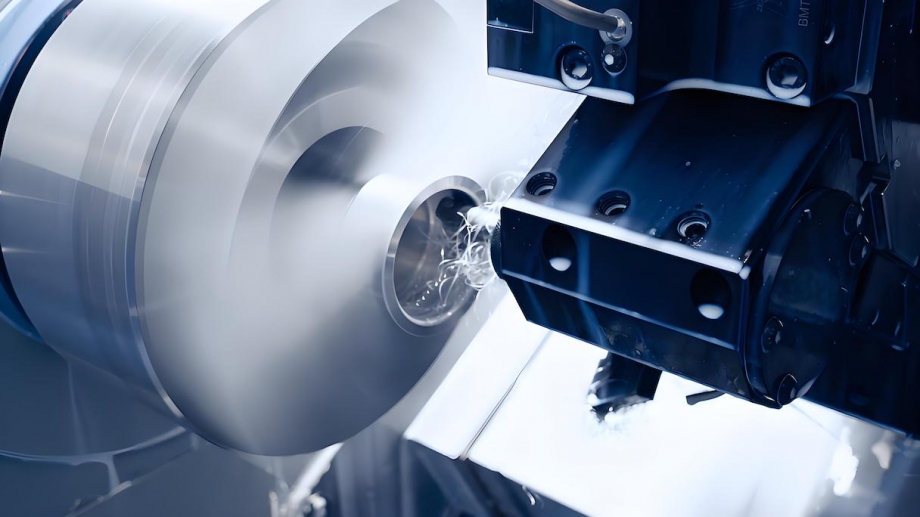

Milling Operation: The CNC machine begins the milling process, using various cutting tools to remove material according to the programmed instructions. The ability to use multiple tools and adjust their speed and feed rates allows for a wide range of machining operations, from rough cutting to fine finishing.

Finishing Touches: After the initial milling, additional processes such as sanding, polishing, or coating may be applied to achieve the desired finish. These finishing processes enhance the aesthetic appeal and functional performance of the final product, ensuring it meets the specific requirements of the application.

Benefits of Custom CNC Milling

Choosing custom CNC milling for your projects comes with numerous advantages that can significantly enhance the quality and efficiency of your manufacturing processes.

Precision and Accuracy

One of the most significant benefits of CNC milling is its ability to produce parts with exceptional precision. The computer-controlled nature of the process minimizes human error, ensuring that each component meets exact specifications. This level of accuracy is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest deviation can lead to catastrophic failures. The precision of CNC milling not only improves product quality but also reduces the need for extensive rework and scrap, ultimately saving time and resources.

Versatility in Material Selection

Custom CNC milling can accommodate a wide variety of materials, including metals, plastics, and composites. This versatility allows manufacturers to select the most suitable material for their specific application, whether it requires strength, flexibility, or resistance to heat and corrosion. The ability to work with different materials also enables the production of hybrid components that combine the best properties of multiple materials, further enhancing performance.

Cost-Effectiveness for Custom Parts

While the initial setup costs for CNC milling can be higher than traditional manufacturing methods, the long-term savings are often substantial. Custom CNC milling is particularly cost-effective for small to medium production runs, as it eliminates the need for expensive tooling and setup changes associated with other manufacturing processes. Additionally, the efficiency of CNC milling reduces labor costs and production times, making it an attractive option for businesses looking to optimize their manufacturing operations.

Rapid Prototyping Capabilities

CNC milling is ideal for rapid prototyping, allowing designers and engineers to quickly create and test prototypes before moving to full-scale production. This capability accelerates the product development cycle, enabling businesses to bring their products to market faster. Rapid prototyping also facilitates iterative design processes, where feedback can be quickly incorporated into subsequent versions of the product, leading to better final outcomes.

Enhanced Design Flexibility

With CNC milling, designers have the freedom to create complex geometries and intricate designs that would be challenging or impossible to achieve with traditional machining methods. This design flexibility opens up new possibilities for innovation and creativity in product development. The ability to produce custom shapes and features allows businesses to differentiate their products in competitive markets, providing a significant advantage.

Applications of Custom CNC Milling

Custom CNC milling is utilized across various industries, each benefiting from its unique capabilities.

Aerospace Industry

In the aerospace sector, precision is paramount. Custom CNC milling is used to manufacture critical components such as engine parts, brackets, and housings. The ability to produce lightweight yet strong components is essential for improving fuel efficiency and performance. Additionally, the stringent safety standards in aerospace manufacturing require that all parts be produced with the highest level of accuracy and reliability, making CNC milling an ideal choice.

Medical Device Manufacturing

The medical industry relies heavily on custom CNC milling for producing surgical instruments, implants, and other medical devices. The high level of precision and the ability to work with biocompatible materials make CNC milling an ideal choice for this sector. Furthermore, the customization capabilities of CNC milling allow for the production of tailored solutions that meet the specific needs of patients and healthcare providers.

Automotive Industry

The automotive industry uses custom CNC milling for creating parts such as engine components, transmission housings, and custom fittings. The ability to produce high-quality, durable parts quickly is essential for meeting the demands of modern automotive manufacturing. As the industry moves towards electric and autonomous vehicles, the need for innovative designs and lightweight materials further emphasizes the importance of CNC milling in automotive applications.

Electronics and Telecommunications

Custom CNC milling is also prevalent in the electronics industry, where it is used to create enclosures, circuit boards, and other components. The precision and repeatability of CNC milling ensure that electronic devices function reliably. As technology continues to advance, the demand for smaller, more complex electronic components increases, making CNC milling a vital process for manufacturers in this field.

Choosing the Right CNC Milling Service

When selecting a custom CNC milling service, several factors should be considered to ensure you receive the best possible results for your project.

Experience and Expertise

Look for a service provider with extensive experience in CNC milling and a proven track record of delivering high-quality parts. An experienced provider will understand the nuances of different materials and machining techniques, ensuring optimal results. Their expertise can also help in troubleshooting potential issues during the design and manufacturing process, leading to smoother project execution.

Technology and Equipment

The quality of the CNC machines and technology used by the service provider is crucial. Advanced CNC milling machines equipped with the latest technology can produce parts with greater precision and efficiency. Additionally, providers that invest in state-of-the-art equipment are often better positioned to handle complex projects and adapt to evolving industry standards.

Quality Assurance Processes

A reputable CNC milling service should have robust quality assurance processes in place. This includes regular inspections, testing, and adherence to industry standards to ensure that every part meets the required specifications. Quality assurance not only enhances product reliability but also builds trust with clients, as they can be confident in the consistency and performance of the parts produced.

Customer Support and Communication

Effective communication is essential throughout the milling process. Choose a service provider that offers excellent customer support, keeping you informed at every stage of production and addressing any concerns promptly. A strong partnership with your CNC milling service can lead to better collaboration, ensuring that your project stays on track and meets deadlines.

Conclusion

Custom CNC milling is a powerful manufacturing solution that offers numerous benefits, including precision, versatility, and cost-effectiveness. Its applications span various industries, making it an essential tool for modern manufacturing. By choosing the right CNC milling service, you can ensure that your next project is executed with the highest level of quality and efficiency.

In summary, whether you are developing a prototype or producing high-volume parts, custom CNC milling can provide the precision and flexibility needed to meet your project requirements. Embrace the advantages of CNC milling and elevate your manufacturing capabilities to new heights.

Frequently Asked Questions regarding Custom CNC Milling

1. What types of materials can be used in CNC milling?

CNC milling can accommodate a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics (like acrylic and polycarbonate), wood, and composites. The choice of material depends on the specific requirements of the project, including strength, weight, and resistance to environmental factors.

2. How does CNC milling compare to traditional machining methods?

CNC milling offers several advantages over traditional machining methods, including higher precision, reduced human error, and the ability to produce complex geometries. While traditional methods may require more manual intervention and setup time, CNC milling automates many processes, leading to faster production times and lower labor costs.

3. What industries benefit the most from custom CNC milling?

Custom CNC milling is widely used in various industries, including aerospace, automotive, medical device manufacturing, electronics, and telecommunications. Each of these sectors requires high precision and the ability to produce complex parts, making CNC milling an ideal solution.

4. How can CNC milling improve the prototyping process?

CNC milling allows for rapid prototyping, enabling designers and engineers to quickly create and test prototypes before full-scale production. This accelerates the product development cycle, allowing for faster iterations and improvements based on testing and feedback.

5. What should I consider when choosing a CNC milling service provider?

When selecting a CNC milling service provider, consider their experience and expertise, the technology and equipment they use, their quality assurance processes, and the level of customer support they offer. A provider with a strong track record and advanced capabilities will be better equipped to meet your project requirements effectively.