Elastomeric 3D printing has emerged as a revolutionary technology in the field of additive manufacturing, particularly for creating flexible product designs. This article explores the unique characteristics of elastomeric materials, the advantages of 3D printing with these materials, and the various applications that benefit from this innovative approach.

Understanding Elastomeric Materials

Definition and Characteristics

Elastomers are a class of polymers that exhibit rubber-like elasticity. They can stretch significantly and return to their original shape, making them ideal for applications requiring flexibility and durability. The key characteristics of elastomeric materials include:

High Elasticity: Elastomers can be stretched to several times their original length without permanent deformation.

Impact Resistance: They can absorb shocks and vibrations, making them suitable for protective applications.

Chemical Resistance: Many elastomers resist degradation from chemicals, oils, and solvents, enhancing their longevity in various environments.

Types of Elastomeric Materials

There are several types of elastomeric materials used in 3D printing, including:

Thermoplastic Polyurethane (TPU): Known for its excellent flexibility and durability, TPU is widely used in various applications, from footwear to medical devices.

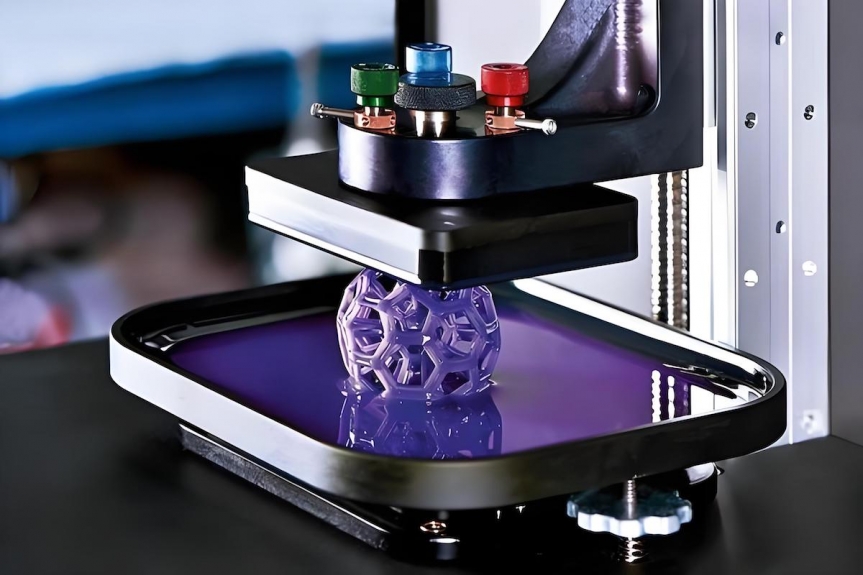

Silicone: This material offers high-temperature resistance and is often used in applications requiring biocompatibility.

Rubber-like Resins: These are used in resin-based 3D printing processes, providing a balance of flexibility and strength.

Advantages of Elastomeric 3D Printing

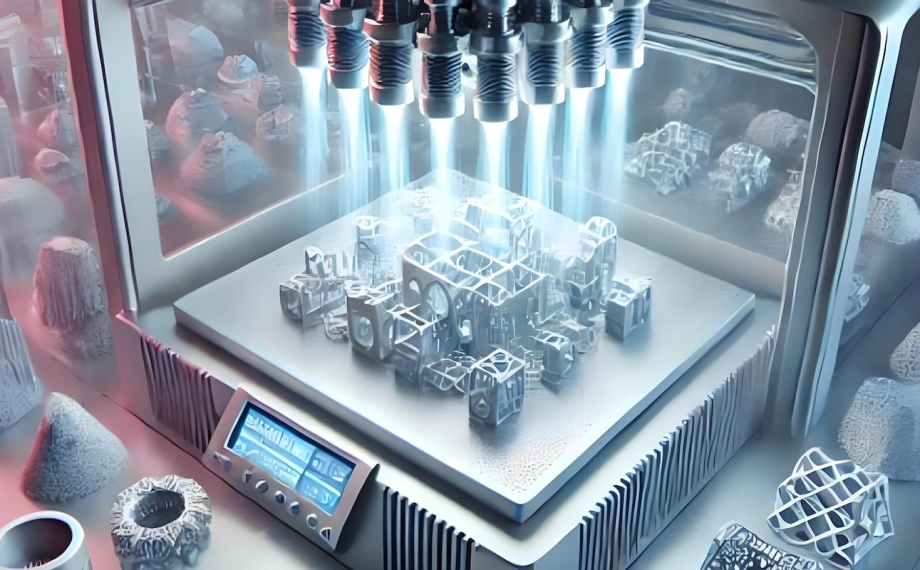

Design Freedom

One of the most significant advantages of elastomeric 3D printing is the design freedom it offers. Traditional manufacturing methods often impose limitations on the complexity of designs. In contrast, 3D printing allows for intricate geometries and customized shapes that can be tailored to specific needs. This capability is particularly beneficial in industries such as fashion, automotive, and healthcare, where unique designs can enhance functionality and aesthetics.

Rapid Prototyping

Elastomeric 3D printing enables rapid prototyping, allowing designers and engineers to create and test multiple iterations of a product quickly. This speed in the design process accelerates product development cycles, enabling companies to bring their products to market faster. The ability to produce prototypes that closely mimic the final product's properties is invaluable for testing and validation.

Cost-Effectiveness

3D printing with elastomeric materials can be more cost-effective than traditional manufacturing methods, especially for small production runs or custom parts. The reduction in material waste and the elimination of complex tooling requirements contribute to lower overall production costs. Additionally, the ability to produce parts on-demand reduces inventory costs and storage needs.

Customization

Elastomeric 3D printing allows for high levels of customization. Products can be designed to meet specific user requirements, such as varying levels of flexibility, hardness, and color. This customization is particularly advantageous in industries like healthcare, where personalized medical devices can significantly improve patient outcomes.

Applications of Elastomeric 3D Printing

Medical Devices

In the medical field, elastomeric 3D printing is used to create custom prosthetics, orthotics, and surgical tools. The flexibility and biocompatibility of elastomers make them ideal for devices that need to conform to the human body. For instance, custom-fit prosthetic limbs can be designed to enhance comfort and functionality for the user.

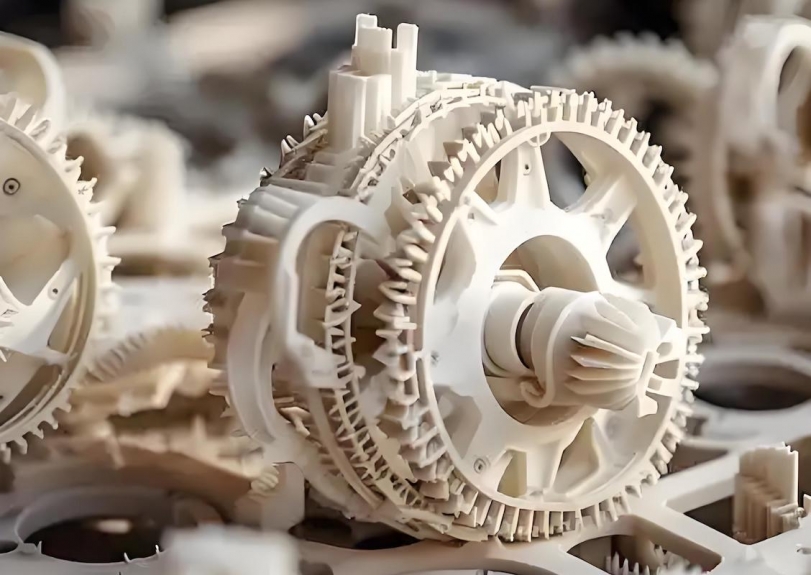

Automotive Components

The automotive industry benefits from elastomeric 3D printing in producing flexible components such as seals, gaskets, and interior parts. These components require durability and flexibility to withstand various environmental conditions. The ability to quickly prototype and produce these parts allows for more innovative designs and improved vehicle performance.

Consumer Products

Elastomeric 3D printing is increasingly used in the production of consumer products, including footwear, wearable technology, and sports equipment. The flexibility of the materials allows for the creation of comfortable and functional products that enhance user experience. For example, custom-fit shoe insoles can be produced to provide better support and comfort.

Robotics and Automation

In robotics, elastomeric materials are used to create soft actuators and grippers that mimic the dexterity of human hands. These soft robotic components can handle delicate objects without causing damage, making them ideal for applications in automation and manufacturing.

Challenges and Considerations

Material Limitations

While elastomeric 3D printing offers numerous advantages, there are challenges associated with the materials themselves. Some elastomers may have limited printability, requiring specific printer settings and conditions to achieve optimal results. Additionally, the mechanical properties of printed elastomers can vary based on the printing process and parameters used.

Post-Processing Requirements

Many elastomeric prints require post-processing to achieve the desired finish and performance characteristics. This can include curing, cleaning, or additional treatments to enhance properties such as strength and durability. Understanding these requirements is essential for achieving high-quality results.

Cost of Equipment

Investing in 3D printing technology for elastomeric materials can be costly. High-quality printers capable of handling flexible materials often come with a higher price tag. However, the long-term benefits of reduced production costs and increased design flexibility can outweigh the initial investment.

Future Trends in Elastomeric 3D Printing

Advancements in Material Science

As research in material science progresses, new elastomeric materials with enhanced properties are being developed. These advancements will likely lead to even greater applications and capabilities in 3D printing, allowing for more complex and functional designs.

Integration with Other Technologies

The integration of elastomeric 3D printing with other technologies, such as digital manufacturing and artificial intelligence, is expected to revolutionize the industry. This integration can lead to smarter design processes, improved production efficiency, and enhanced product performance.

Sustainability Considerations

With growing concerns about environmental impact, the development of sustainable elastomeric materials is becoming increasingly important. Biodegradable and recyclable elastomers are being explored to reduce waste and promote sustainability in 3D printing.

Conclusion

Elastomeric 3D printing stands at the forefront of innovation in flexible product design. Its unique properties, combined with the advantages of additive manufacturing, make it an ideal choice for a wide range of applications. As technology continues to evolve, the potential for elastomeric 3D printing will only expand, paving the way for new and exciting possibilities in design and manufacturing. The future of flexible product design is bright, and elastomeric 3D printing will undoubtedly play a crucial role in shaping it.

Frequently Asked Questions regarding 3D Printing

1. What are the primary benefits of using elastomeric materials in 3D printing?

Answer: The primary benefits of using elastomeric materials in 3D printing include high elasticity, impact resistance, chemical resistance, design freedom, rapid prototyping, cost-effectiveness, and the ability to create highly customized products tailored to specific user needs.

2. How does elastomeric 3D printing differ from traditional manufacturing methods?

Answer: Elastomeric 3D printing differs from traditional manufacturing methods in that it allows for the creation of complex geometries and customized designs without the need for extensive tooling. It also enables rapid prototyping, reducing the time and cost associated with product development compared to conventional methods.

3. What types of applications benefit most from elastomeric 3D printing?

Answer: Applications that benefit most from elastomeric 3D printing include medical devices (such as prosthetics and orthotics), automotive components (like seals and gaskets), consumer products (such as footwear and sports equipment), and robotics (soft actuators and grippers).

4. What challenges are associated with elastomeric 3D printing?

Answer: Challenges associated with elastomeric 3D printing include material limitations (such as printability and mechanical properties), post-processing requirements (to achieve desired finishes), and the high cost of specialized 3D printing equipment capable of handling flexible materials.

5. What future trends can we expect in elastomeric 3D printing?

Answer: Future trends in elastomeric 3D printing may include advancements in material science leading to new elastomers with enhanced properties, integration with digital manufacturing and AI for smarter design processes, and the development of sustainable elastomeric materials to address environmental concerns.