Die casting is a highly efficient manufacturing process used to produce metal parts with high precision and excellent surface finish. However, to achieve optimal results, several design considerations must be taken into account. This article explores the key factors that influence the die casting process, ensuring that designers and engineers can create parts that meet both functional and aesthetic requirements.

Understanding Die Casting

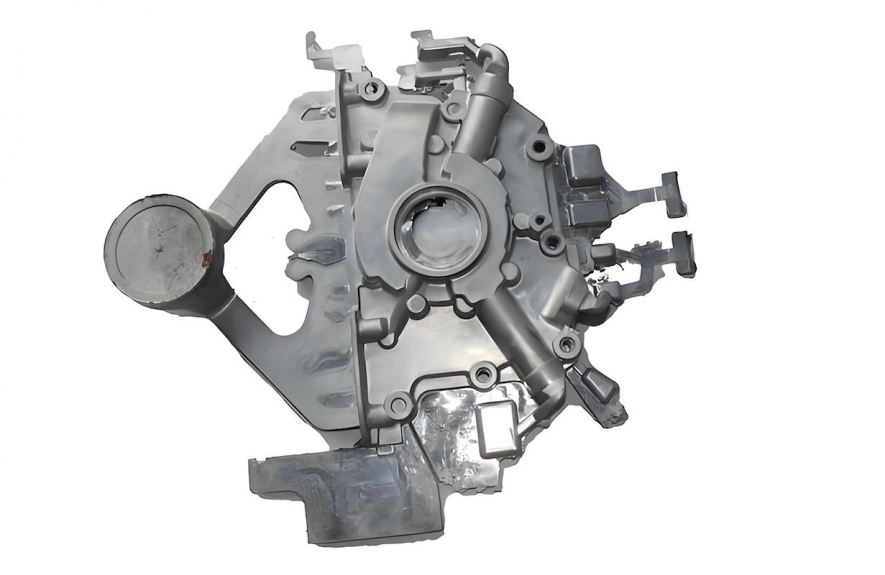

Die casting involves forcing molten metal into a mold cavity under high pressure. This process is particularly suitable for producing complex shapes with tight tolerances. The most commonly used materials in die casting include aluminum, zinc, and magnesium alloys. Each material has its unique properties, which can affect the design and performance of the final product. For instance, aluminum is known for its lightweight and corrosion-resistant properties, making it ideal for applications in the automotive and aerospace industries. Zinc, with its excellent fluidity, is often used for smaller, intricate parts, while magnesium is favored for its strength-to-weight ratio, making it suitable for high-performance applications.

Advantages of Die Casting

Die casting offers several advantages, including high production rates, excellent dimensional accuracy, smooth surface finishes, the ability to produce complex shapes, and reduced machining requirements. These benefits make die casting a preferred choice for many industries, including automotive, aerospace, and consumer goods. The high production rates allow manufacturers to meet large-scale demands efficiently, while the precision of die casting minimizes the need for secondary operations, thus reducing overall production costs. Additionally, the ability to create intricate designs without compromising strength or durability makes die casting an attractive option for innovative product development.

Key Design Considerations

When designing parts for die casting, several critical factors must be considered to ensure the success of the process.

Material Selection

The choice of material is fundamental in die casting. Different metals have varying properties, such as strength, weight, and corrosion resistance. For instance, aluminum is lightweight and has excellent corrosion resistance, making it ideal for automotive applications. Zinc, on the other hand, is often used for smaller, intricate parts due to its good fluidity and lower melting point. The selection of the right material not only affects the performance of the final product but also influences the cost and manufacturability of the part. Designers must consider the specific requirements of the application, including environmental factors, load-bearing capabilities, and aesthetic considerations, to choose the most suitable material.

Wall Thickness

Uniform wall thickness is crucial in die casting. Variations in thickness can lead to issues such as uneven cooling, which may cause warping or cracking. Designers should aim for consistent wall thickness throughout the part, typically between 1.5 mm to 6 mm, depending on the material used. Thicker sections may require additional design features, such as ribs or bosses, to maintain structural integrity. Moreover, maintaining uniform wall thickness not only enhances the mechanical properties of the part but also ensures a more efficient filling of the mold, reducing the likelihood of defects and improving overall production efficiency.

Draft Angles

Draft angles are essential for the easy removal of the casting from the mold. A draft angle of 1 to 3 degrees is generally recommended, depending on the complexity of the part. Insufficient draft can lead to difficulty in ejection, resulting in damage to the part or the mold. Designers should incorporate draft angles into vertical surfaces to facilitate smooth ejection. Additionally, the inclusion of draft angles can help reduce wear on the mold over time, extending its lifespan and reducing maintenance costs. Properly designed draft angles also contribute to the overall quality of the casting, ensuring that the final product meets the desired specifications.

Ribs and Bosses

Ribs and bosses are structural features that enhance the strength and rigidity of a part without significantly increasing its weight. Ribs should be designed with a thickness of about 50% of the wall thickness to avoid issues during the casting process. Bosses, which are raised features used for fastening or assembly, should also be designed with appropriate dimensions to ensure they do not interfere with the mold's operation. The strategic placement of ribs and bosses can improve the load distribution within the part, enhancing its performance under stress. Furthermore, these features can also aid in the alignment and assembly of components, contributing to the overall functionality of the final product.

Fillets and Radii

Sharp corners can create stress concentrations, leading to potential failure points in the casting. To mitigate this risk, designers should incorporate fillets and radii at corners and edges. A larger radius can help distribute stress more evenly and improve the flow of molten metal during casting. The recommended radius is typically 1.5 times the wall thickness. By designing with fillets and radii, manufacturers can enhance the durability of the part, reducing the likelihood of cracks or fractures during use. This design consideration is particularly important in high-stress applications, where the integrity of the part is critical to its performance and safety.

Parting Lines

The parting line is where the two halves of the mold meet. Proper placement of the parting line is critical to minimize visible seams on the finished part. Designers should consider the aesthetics and functionality of the part when determining the location of the parting line. Ideally, it should be placed in a way that does not interfere with the part's design or performance. Additionally, careful consideration of the parting line can help streamline the manufacturing process, reducing the need for additional finishing work to conceal seams. A well-placed parting line can also facilitate easier mold maintenance and repair, contributing to the overall efficiency of the production process.

Ejection Pins

Ejection pins are used to push the finished part out of the mold. Their placement is vital to ensure even ejection and to avoid damaging the part. Designers should strategically position ejection pins to minimize marks on the surface and ensure that they do not interfere with any critical features of the part. The design of ejection pins should also consider the potential for wear and tear, as well as the need for maintenance. Properly designed ejection systems can enhance the overall efficiency of the die casting process, reducing cycle times and improving productivity.

Gate Design

Gates are the entry points through which molten metal flows into the mold cavity. The design of the gate can significantly impact the filling of the mold and the quality of the casting. Designers should consider the size, shape, and location of the gate to ensure optimal metal flow and minimize turbulence, which can lead to defects. The choice of gate design can also influence the cooling rate of the casting, affecting its mechanical properties. By optimizing gate design, manufacturers can improve the overall quality of the casting while also reducing material waste and production costs.

Cooling and Solidification

The cooling rate of the molten metal affects the final properties of the casting. Designers should consider the cooling channels within the mold to ensure uniform cooling. Uneven cooling can lead to warping or internal stresses. Additionally, the solidification time should be optimized to balance production speed and part quality. Effective cooling strategies can enhance the mechanical properties of the casting, such as strength and hardness, while also reducing the risk of defects. By carefully designing the cooling system, manufacturers can achieve a more consistent and reliable production process.

Surface Finish

The surface finish of the casting is an important consideration, especially for aesthetic applications. Die casting typically produces a smooth surface, but additional finishing processes may be required for specific applications. Designers should specify the desired surface finish and consider how it will be achieved during the design phase. A high-quality surface finish not only enhances the appearance of the part but also improves its performance by reducing friction and wear. Furthermore, a well-finished surface can contribute to better corrosion resistance, extending the lifespan of the product in its intended application.

Tolerances

Tolerances define the allowable variation in dimensions and are critical in die casting. Designers should specify tolerances based on the part's function and the capabilities of the die casting process. Tight tolerances may require additional machining, which can increase production costs. It is essential to balance the need for precision with cost-effectiveness. By understanding the capabilities of the die casting process, designers can set realistic tolerances that ensure the functionality of the part while minimizing unnecessary expenses. This consideration is particularly important in industries where precision is critical, such as aerospace and medical devices.

Conclusion

Die casting is a versatile manufacturing process that can produce high-quality parts with complex geometries. By considering the various design factors outlined in this article, designers can optimize their die casting projects for performance, cost, and manufacturability. Understanding the intricacies of material selection, wall thickness, draft angles, and other design considerations will lead to successful die casting outcomes, ultimately benefiting the end product and its application. As industries continue to evolve and demand more innovative solutions, the importance of thoughtful design in die casting will only grow, paving the way for advancements in manufacturing technology and product development.

Frequently Asked Questions regarding Die Casting

1. What types of materials are commonly used in die casting?

Answer: The most commonly used materials in die casting include aluminum, zinc, magnesium, and copper alloys. Aluminum is favored for its lightweight and corrosion resistance, zinc is used for its excellent fluidity and lower melting point, magnesium is chosen for its strength-to-weight ratio, and copper alloys are utilized for their high thermal and electrical conductivity.

2. How does wall thickness affect the die casting process?

Answer: Wall thickness is critical in die casting as it influences the cooling rate, strength, and overall quality of the casting. Uniform wall thickness helps prevent issues like warping and cracking. Designers typically aim for a thickness between 1.5 mm to 6 mm, depending on the material, to ensure optimal filling and cooling during the casting process.

3. Why are draft angles important in die casting design?

Answer: Draft angles are essential for the easy removal of the casting from the mold. They help reduce friction between the mold and the part during ejection, preventing damage to both the part and the mold. A draft angle of 1 to 3 degrees is generally recommended to facilitate smooth ejection and maintain the integrity of the casting.

4. What role do ribs and bosses play in die casting?

Answer: Ribs and bosses are structural features that enhance the strength and rigidity of a part without significantly increasing its weight. Ribs provide additional support, while bosses are used for fastening or assembly. Properly designed ribs and bosses can improve load distribution and overall performance, making the part more durable and functional.

5. How can surface finish requirements impact the die casting process?

Answer: Surface finish requirements can significantly impact the die casting process as they dictate the level of post-processing needed. A smoother surface finish may require additional machining or finishing processes, which can increase production costs and time. Designers must specify the desired surface finish early in the design phase to ensure that the die casting process can meet these requirements efficiently.