CNC (Computer Numerical Control) turning is a vital process in modern manufacturing, allowing for the precise shaping of materials into various components. This technology has revolutionized the way parts are produced, enabling manufacturers to achieve high levels of accuracy and repeatability. However, like any advanced manufacturing technique, CNC turning services face several challenges that can impact efficiency, quality, and overall production costs. This article explores these challenges in detail and provides strategies for overcoming them.

Understanding CNC Turning

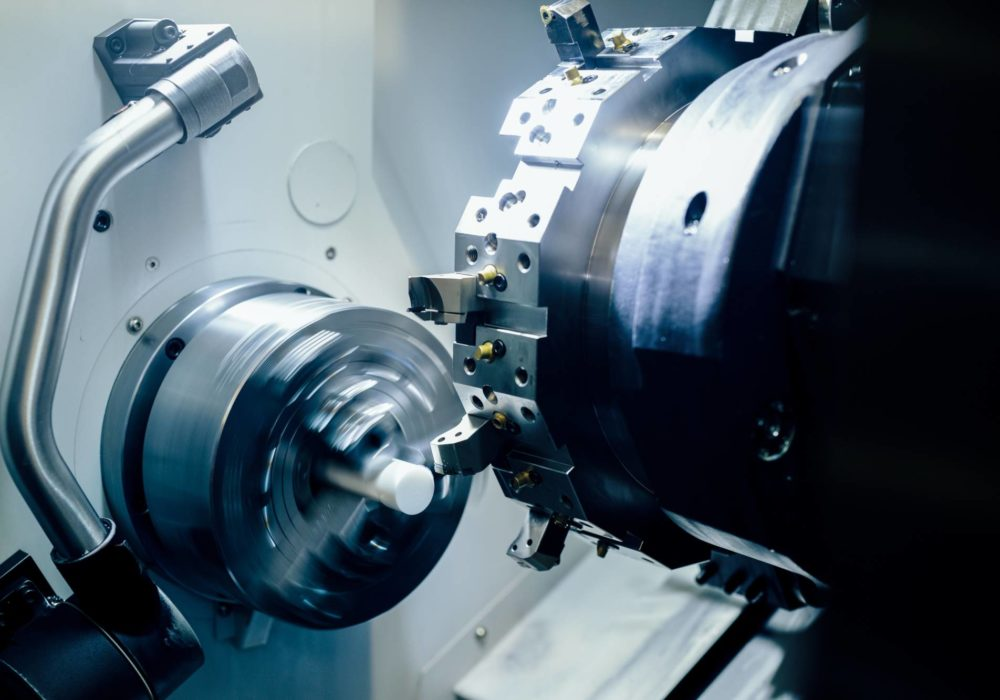

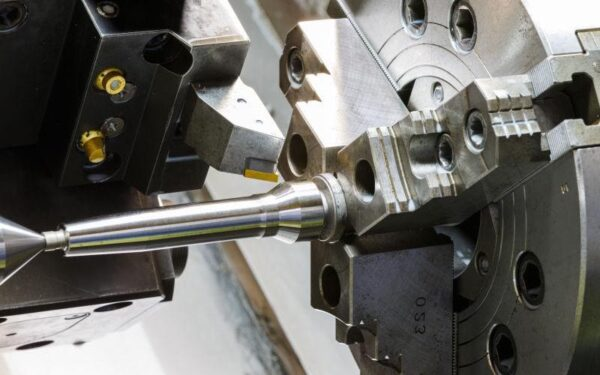

CNC turning involves the use of a lathe machine to rotate a workpiece against a cutting tool. This process is essential for creating cylindrical parts with high precision. The automation of this process through CNC technology enhances productivity and accuracy, making it a preferred choice in industries such as aerospace, automotive, and medical device manufacturing. The ability to program complex geometries and execute them with minimal human intervention has made CNC turning indispensable in high-volume production environments. Moreover, the integration of advanced software and machine learning algorithms is paving the way for even greater efficiencies and capabilities in CNC turning operations.

Common Challenges in CNC Turning Services

1. Tool Wear and Tear

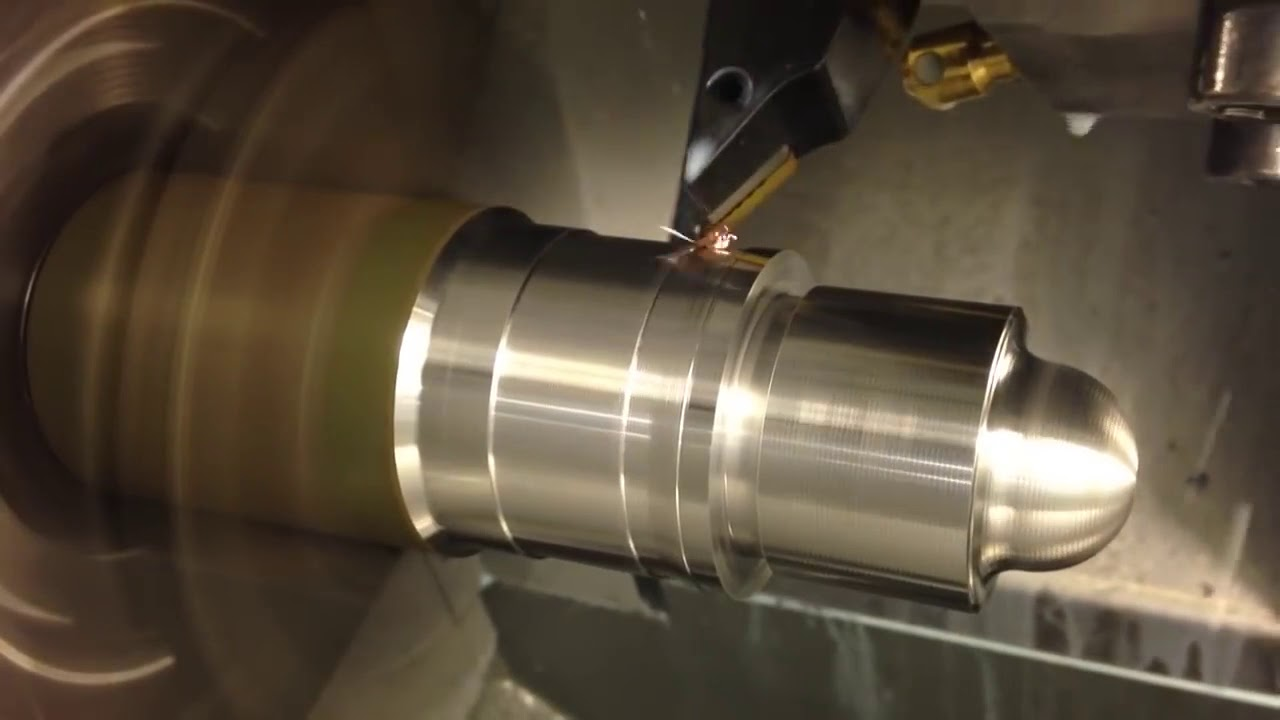

One of the most significant challenges in CNC turning is tool wear. As tools are subjected to high speeds and pressures, they can degrade over time, leading to reduced cutting efficiency and compromised part quality. Tool wear not only affects the surface finish of the machined parts but can also lead to dimensional inaccuracies, which are critical in industries where precision is paramount.

Strategies to Overcome Tool Wear

To mitigate tool wear, manufacturers can implement several strategies. Regular tool inspection is crucial; frequent checks can help identify wear early, allowing for timely replacements before they affect production. Optimizing cutting parameters, such as adjusting feed rates and speeds, can significantly reduce the stress on tools, prolonging their lifespan. Additionally, using coated tools can enhance durability and reduce friction, which is particularly beneficial when machining harder materials. Investing in high-quality tooling and maintaining a well-organized tool inventory can also contribute to minimizing downtime and ensuring consistent production quality.

2. Material Variability

Different materials exhibit varying properties, which can affect the CNC turning process. For instance, harder materials may require different cutting speeds and tools compared to softer ones. Material variability can lead to challenges in achieving consistent quality and may necessitate frequent adjustments to machining parameters, which can disrupt production flow.

Strategies to Manage Material Variability

To address material variability, manufacturers should conduct thorough material testing to understand the specific properties of the materials they are working with. This knowledge can inform better machining strategies tailored to each material type. Adjusting tooling and parameters based on the material characteristics can improve outcomes and reduce the likelihood of defects. Furthermore, establishing strong relationships with material suppliers can ensure access to high-quality materials that meet the required specifications.

3. Complex Geometries

As designs become more intricate, CNC turning faces challenges in producing complex geometries. Parts with tight tolerances and intricate features can be difficult to machine accurately, often requiring multiple setups or specialized tooling. The complexity of these designs can lead to increased production times and higher costs, particularly if errors occur during machining.

Strategies for Handling Complex Geometries

To effectively manage complex geometries, manufacturers can utilize advanced software for computer-aided design (CAD) and computer-aided manufacturing (CAM). These tools can help in planning and simulating machining processes for complex designs, allowing for the identification of potential issues before actual production begins. Investing in multi-axis machines can also enhance capabilities, as these machines can handle more complex shapes and reduce the need for multiple setups, thereby improving efficiency and reducing lead times.

4. Machine Downtime

Unplanned machine downtime can significantly impact production schedules and costs. Issues such as mechanical failures, software glitches, or maintenance can lead to delays that disrupt the entire manufacturing process. The financial implications of downtime can be substantial, affecting not only immediate production but also customer satisfaction and long-term business relationships.

Strategies to Minimize Downtime

To reduce machine downtime, manufacturers should implement predictive maintenance strategies. By using sensors and data analytics, they can monitor machine performance and predict when maintenance is needed before failures occur. This proactive approach can help avoid unexpected breakdowns. Additionally, maintaining a well-stocked inventory of essential spare parts can reduce repair times and keep production running smoothly. Regular training for operators on troubleshooting and basic maintenance can also empower them to address minor issues before they escalate.

5. Programming Challenges

Programming CNC machines can be complex, especially for intricate designs. Errors in programming can lead to production delays and defective parts, which can be costly to rectify. The learning curve associated with programming can also be steep, particularly for new operators who may not be familiar with the intricacies of CNC technology.

Strategies to Improve Programming Efficiency

To enhance programming efficiency, manufacturers can invest in regular training for operators to improve their programming skills and reduce errors. This training should cover not only the basics of CNC programming but also advanced techniques and troubleshooting methods. Utilizing simulation software can also be beneficial, as it allows operators to visualize the machining process and identify potential issues before actual production. This can lead to more efficient programming and a reduction in costly mistakes.

6. Quality Control Issues

Ensuring consistent quality in CNC turning is crucial. Variations in part quality can arise from several factors, including tool wear, material inconsistencies, and machine calibration. In industries where precision is critical, even minor deviations can lead to significant problems, including product recalls and loss of customer trust.

Strategies for Effective Quality Control

To maintain high-quality standards, manufacturers should implement statistical process control (SPC) methods. This approach helps monitor and control the machining process to ensure consistent quality throughout production. Regular calibration of machines is essential to prevent quality issues, as even slight misalignments can lead to defects. Additionally, establishing a robust quality assurance program that includes regular inspections and testing can help catch issues early and ensure that only high-quality parts reach customers.

7. Cost Management

CNC turning can be expensive, particularly when considering the costs of materials, tools, and machine operation. Managing these costs while maintaining quality is a significant challenge for manufacturers. Fluctuations in material prices and the need for high-quality tooling can further complicate cost management efforts.

Strategies for Cost Management

To effectively manage costs, manufacturers can optimize production processes to streamline operations and reduce waste. Implementing lean manufacturing principles can help identify areas for improvement and eliminate inefficiencies. Negotiating with suppliers to secure better pricing on materials and tools can also contribute to cost savings. Additionally, investing in technology that enhances productivity can lead to long-term cost reductions, making CNC turning services more competitive in the market.

Conclusion

CNC turning services are essential in various industries, but they come with their own set of challenges. By understanding these challenges and implementing effective strategies, manufacturers can enhance their CNC turning operations, improve product quality, and reduce costs. Continuous improvement and adaptation to new technologies will be key in overcoming these challenges and ensuring the success of CNC turning services in the future. As the industry evolves, staying informed about advancements in CNC technology and best practices will be crucial for maintaining a competitive edge.

Frequently Asked Questions regarding CNC Turning Service

1. What is CNC turning, and how does it work?

CNC turning is a manufacturing process that uses computer numerical control to automate the rotation of a workpiece against a cutting tool. The CNC machine interprets programmed instructions to precisely shape materials into cylindrical parts. The process involves feeding the material into the lathe, where it is rotated while the cutting tool removes material to achieve the desired shape and dimensions.

2. What are the advantages of using CNC turning over traditional machining methods?

CNC turning offers several advantages over traditional machining methods, including higher precision and repeatability, reduced human error, and the ability to produce complex geometries with ease. Additionally, CNC machines can operate continuously, leading to increased productivity and efficiency. The automation of the process also allows for quicker setup times and the ability to run multiple jobs with minimal intervention.

3. How can manufacturers reduce tool wear in CNC turning?

Manufacturers can reduce tool wear by regularly inspecting tools for signs of degradation, optimizing cutting parameters such as speed and feed rates, and using high-quality, coated cutting tools. Implementing a preventive maintenance schedule for machines can also help maintain optimal performance and extend tool life.

4. What role does quality control play in CNC turning services?

Quality control is crucial in CNC turning services to ensure that the produced parts meet specified tolerances and quality standards. Implementing statistical process control (SPC) methods, regular machine calibration, and thorough inspections throughout the production process helps identify and rectify any issues early, ensuring consistent quality and reducing the risk of defects.

5. What are some common materials used in CNC turning, and how do they affect the process?

Common materials used in CNC turning include metals such as aluminum, steel, brass, and titanium, as well as plastics and composites. The choice of material affects the cutting speed, tool selection, and machining parameters. Harder materials may require specialized tools and slower cutting speeds to prevent tool wear, while softer materials can be machined more quickly and easily. Understanding the properties of each material is essential for optimizing the CNC turning process.