CNC milling has revolutionized the prototyping process across various industries, offering numerous advantages that enhance efficiency, precision, and flexibility. This article delves into the key benefits of CNC milling services for prototyping, exploring how this technology can significantly improve product development cycles.

Understanding CNC Milling

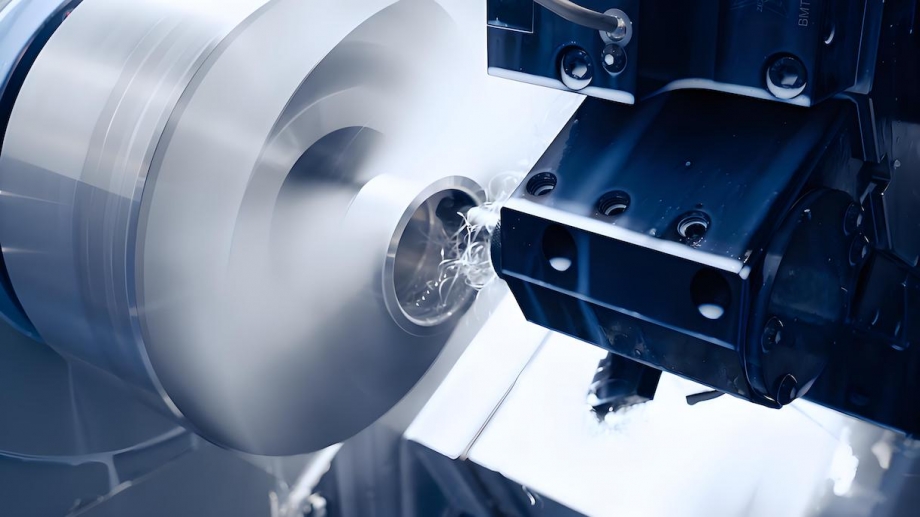

CNC (Computer Numerical Control) milling is a manufacturing process that utilizes computer-controlled machines to remove material from a workpiece. This process allows for the creation of complex shapes and designs with high precision. CNC milling is widely used in prototyping due to its ability to produce parts quickly and accurately. The technology operates by interpreting a digital design file, which guides the machine in executing precise movements to shape the material. This level of automation not only streamlines the manufacturing process but also minimizes human error, leading to more reliable outcomes.

The Role of CNC Milling in Prototyping

Prototyping is a crucial phase in product development, allowing designers and engineers to create tangible models of their concepts. CNC milling plays a vital role in this process by enabling rapid production of prototypes that can be tested and refined before mass production. The ability to quickly iterate on designs is essential in today's fast-paced market, where consumer preferences and technological advancements are constantly evolving. By utilizing CNC milling, companies can ensure that their prototypes are not only functional but also aligned with market demands.

Advantages of CNC Milling for Prototyping

High Precision and Accuracy

One of the most significant advantages of CNC milling is its ability to produce parts with exceptional precision. CNC machines operate based on digital designs, ensuring that every cut and shape is executed with high accuracy. This level of precision is essential for prototypes, especially in industries such as aerospace, automotive, and medical devices, where even the slightest deviation can lead to significant issues. The accuracy of CNC milling allows engineers to create prototypes that closely resemble the final product, facilitating more effective testing and validation processes.

Speed of Production

CNC milling significantly reduces the time required to produce prototypes. Traditional manufacturing methods often involve lengthy setup times and manual labor, which can slow down the prototyping process. In contrast, CNC milling machines can operate continuously, allowing for rapid production of multiple prototypes in a fraction of the time. This speed enables companies to bring their products to market faster, gaining a competitive edge. The ability to quickly produce prototypes also allows for more extensive testing and refinement, ensuring that the final product meets all necessary specifications and quality standards.

Material Versatility

CNC milling can work with a wide range of materials, including metals, plastics, and composites. This versatility allows designers to choose the most suitable material for their prototypes, ensuring that the final product meets the desired specifications and performance criteria. Whether creating a prototype from aluminum, steel, or a specialized plastic, CNC milling can accommodate various material requirements. This adaptability is particularly beneficial in industries where specific material properties are critical, such as in the production of lightweight components for aerospace applications or durable parts for automotive use.

Cost-Effectiveness

While the initial investment in CNC milling technology can be significant, the long-term cost savings are substantial. The efficiency of CNC milling reduces labor costs and minimizes material waste, making it a cost-effective solution for prototyping. Additionally, the ability to produce high-quality prototypes quickly can lead to reduced development costs and faster time-to-market, further enhancing overall profitability. By lowering the costs associated with prototyping, companies can allocate resources to other critical areas of development, such as research and marketing.

Flexibility in Design Changes

CNC milling allows for easy modifications to designs, which is particularly beneficial during the prototyping phase. If a design change is necessary, the digital files can be quickly updated, and the CNC machine can produce the revised prototype without the need for extensive retooling. This flexibility enables teams to iterate on their designs rapidly, leading to better final products. The ability to adapt to changes in design not only improves the quality of the prototypes but also fosters a culture of innovation within the organization, encouraging teams to explore new ideas without the fear of incurring significant costs.

Capability for Complex Geometries

CNC milling excels at producing complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. This capability is particularly advantageous for prototyping intricate designs, as it allows engineers to test and validate innovative concepts. The ability to create detailed features and complex shapes enhances the functionality and aesthetics of prototypes. Moreover, this capability opens up new possibilities for product design, enabling engineers to push the boundaries of creativity and functionality in their prototypes.

Consistency and Reproducibility

CNC milling ensures that each prototype produced is consistent and reproducible. Once a design is programmed into the CNC machine, it can produce identical parts with the same specifications repeatedly. This consistency is crucial for testing and validation, as it allows engineers to rely on the prototypes for accurate performance assessments. The reproducibility of CNC milling also simplifies the transition from prototyping to production, as manufacturers can confidently scale up their processes knowing that the quality will remain consistent.

Enhanced Automation

The automation of CNC milling processes reduces the potential for human error, leading to higher quality prototypes. Automated systems can monitor and adjust the machining process in real-time, ensuring optimal performance and minimizing defects. This level of automation not only improves the quality of the prototypes but also allows skilled workers to focus on more complex tasks that require human intervention. By streamlining the manufacturing process, companies can enhance productivity and ensure that their resources are utilized effectively.

Improved Surface Finish

CNC milling can achieve superior surface finishes compared to traditional machining methods. The precision of CNC machines allows for finer cuts and smoother surfaces, which is essential for prototypes that require aesthetic appeal or specific functional characteristics. A better surface finish can also enhance the performance of the final product, particularly in applications where friction or wear is a concern. The ability to produce prototypes with high-quality finishes not only improves their visual appeal but also contributes to their overall functionality and durability.

Integration with Other Technologies

CNC milling can be easily integrated with other manufacturing technologies, such as 3D printing and laser cutting. This integration allows for a more comprehensive approach to prototyping, enabling teams to leverage the strengths of multiple technologies. For instance, a prototype may be partially 3D printed and then finished using CNC milling to achieve the desired precision and surface quality. This synergy between technologies enhances the prototyping process, allowing for more innovative designs and efficient production methods.

Conclusion

CNC milling offers a multitude of advantages for prototyping, making it an invaluable tool in modern manufacturing. Its high precision, speed, material versatility, and cost-effectiveness contribute to more efficient product development cycles. As industries continue to evolve and demand faster, more innovative solutions, CNC milling will remain at the forefront of prototyping technologies, enabling companies to bring their ideas to life with unparalleled accuracy and efficiency.

By embracing CNC milling services, businesses can enhance their prototyping processes, reduce time-to-market, and ultimately deliver higher-quality products to their customers. The integration of CNC milling into the prototyping phase not only streamlines production but also fosters a culture of innovation, allowing companies to stay ahead in a competitive landscape.

Frequently Asked Questions regarding CNC Milling For Prototyping

1. What types of materials can be used in CNC milling for prototyping?

CNC milling can work with a wide variety of materials, including metals such as aluminum, steel, and titanium, as well as plastics like ABS, nylon, and polycarbonate. Additionally, it can handle composite materials, making it versatile for different prototyping needs.

2. How does CNC milling improve the prototyping process compared to traditional methods?

CNC milling improves the prototyping process by offering higher precision, faster production speeds, and the ability to create complex geometries. Unlike traditional methods, CNC milling reduces human error and material waste, leading to more efficient and cost-effective prototyping.

3. Can design changes be easily implemented during the CNC milling process?

Yes, design changes can be easily implemented during the CNC milling process. Since CNC machines operate based on digital files, any modifications to the design can be quickly updated in the software, allowing for rapid production of revised prototypes without extensive retooling.

4. What are the advantages of using CNC milling for complex geometries in prototypes?

CNC milling excels at producing complex geometries that may be difficult or impossible to achieve with traditional manufacturing methods. This capability allows engineers to test innovative designs and create prototypes with intricate features, enhancing both functionality and aesthetics.

5. How does CNC milling contribute to cost savings in prototyping?

CNC milling contributes to cost savings in prototyping by reducing labor costs, minimizing material waste, and speeding up production times. The efficiency of CNC machines allows for the quick turnaround of high-quality prototypes, which can lead to lower overall development costs and faster time-to-market.