LED linear lenses are crucial components in modern lighting design, particularly for applications requiring uniform light distribution and efficiency. As lighting engineers, understanding the specifications of LED linear lenses is essential for selecting the right products for various projects. This article delves into the key parameters that define LED linear lenses, their applications, and considerations for lighting engineers.

What are LED Linear Lenses?

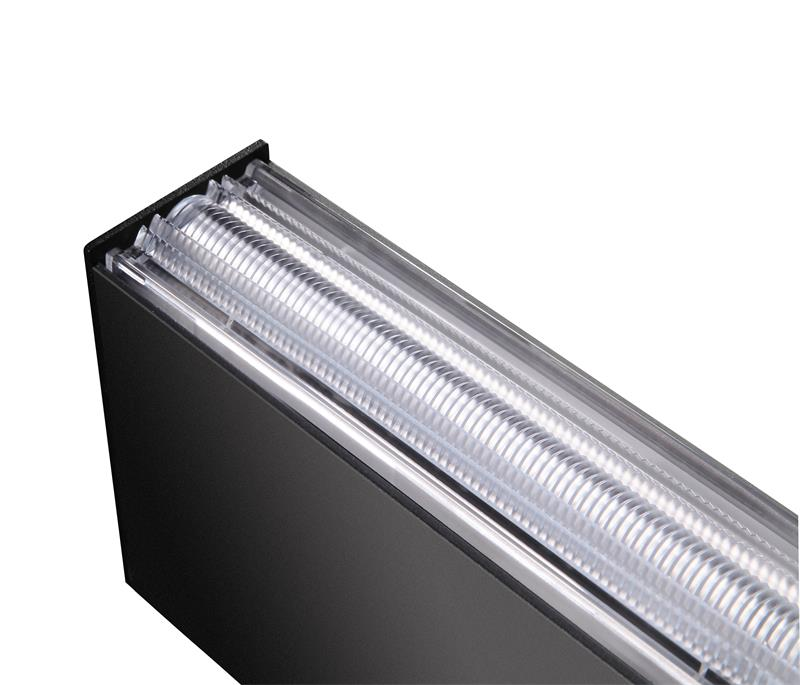

LED linear lenses are optical devices designed to manipulate the light emitted from LED sources. They serve to enhance the performance of LED lighting by controlling the direction, intensity, and distribution of light. These lenses are typically used in linear lighting fixtures, which are popular in commercial, industrial, and residential settings. The design of these lenses allows for a variety of lighting effects, making them versatile tools in the hands of lighting designers.

Key Functions of LED Linear Lenses

1. Light Distribution: Lenses help in shaping the light output, allowing for specific beam angles and patterns. This capability is particularly important in environments where uniform lighting is necessary, such as in offices or retail spaces, where shadows can detract from the overall aesthetic and functionality.

2. Efficiency: By optimizing light output, lenses can improve the overall efficiency of LED systems, reducing energy consumption. This efficiency not only lowers operational costs but also contributes to sustainability efforts, making LED linear lenses an environmentally friendly choice.

3. Aesthetic Appeal: Lenses can enhance the visual quality of lighting, contributing to the overall design of a space. The right lens can create dramatic effects, highlight architectural features, or provide a soft, diffused light that enhances the ambiance of a room.

Essential Parameters for LED Linear Lenses

When selecting LED linear lenses, several critical parameters must be considered:

1. Focal Length

The focal length of a lens determines how light is focused and distributed. Shorter focal lengths produce wider beam angles, while longer focal lengths create narrower beams. This parameter is crucial for applications requiring specific lighting effects, such as wall washing or accent lighting. Understanding the focal length helps engineers design lighting that meets the specific needs of a space, whether it's for highlighting artwork or providing general illumination.

2. Beam Angle

The beam angle is the angle at which light is emitted from the lens. Common beam angles for LED linear lenses range from 15° to 120°. A narrow beam angle is suitable for focused lighting, while a wider angle is ideal for general illumination. Choosing the correct beam angle is essential for achieving the desired lighting effect and ensuring that the light reaches the intended areas without excessive spill or shadowing.

3. Material

The material of the lens affects its optical properties, durability, and cost. Common materials include polycarbonate and acrylic. Polycarbonate lenses are more impact-resistant, making them suitable for high-traffic areas or outdoor applications, while acrylic lenses offer better optical clarity, enhancing the quality of light output. The choice of material can also influence the overall weight and installation requirements of the lighting fixture.

4. Transmittance

Transmittance refers to the percentage of light that passes through the lens. High transmittance is desirable as it ensures maximum light output. Lenses with low transmittance can significantly reduce the efficiency of LED systems, leading to higher energy costs and diminished lighting performance. Engineers must consider transmittance when selecting lenses to ensure that they achieve the desired brightness and effectiveness in their designs.

5. Color Rendering Index (CRI)

The CRI measures how accurately a light source displays colors compared to natural light. A higher CRI (above 80) is preferred for applications where color accuracy is critical, such as in retail or art galleries. In these environments, the ability to render colors faithfully can influence customer perceptions and enhance the overall experience. Lighting engineers should prioritize CRI when designing spaces where color fidelity is essential.

6. Thermal Management

Effective thermal management is essential for maintaining the performance and longevity of LED systems. Lenses should be designed to dissipate heat effectively, preventing damage to the LED components. Poor thermal management can lead to reduced light output and a shorter lifespan for the LEDs, making it a critical consideration in the design and selection of LED linear lenses.

7. UV Resistance

For outdoor applications, UV resistance is crucial to prevent degradation of the lens material over time. Lenses should be treated or made from materials that can withstand UV exposure. This resistance ensures that the lenses maintain their optical properties and structural integrity, providing reliable performance in various environmental conditions.

Applications of LED Linear Lenses

LED linear lenses are versatile and can be used in various applications, including:

- Commercial Lighting: In retail environments, LED linear lenses help create inviting atmospheres by providing uniform lighting. This uniformity is essential for showcasing products effectively and enhancing the shopping experience.

- Architectural Lighting: These lenses are used in architectural features to highlight structures and create visual interest. By directing light precisely, they can accentuate design elements and enhance the overall aesthetic of a building.

- Industrial Lighting: In warehouses and factories, LED linear lenses provide efficient lighting solutions that enhance visibility and safety. Proper lighting is crucial in these settings to prevent accidents and improve productivity.

- Residential Lighting: Homeowners use LED linear lenses in kitchens, living rooms, and outdoor spaces for both functional and aesthetic purposes. The versatility of these lenses allows for creative lighting designs that enhance the comfort and style of living spaces.

Choosing the Right LED Linear Lens Supplier

Selecting a reliable LED linear lens supplier is crucial for ensuring quality and performance. Here are some factors to consider:

1. Reputation and Experience

Choose suppliers with a proven track record in the industry. Experienced suppliers are more likely to provide high-quality products and reliable customer service. A supplier's reputation can often be gauged through customer reviews and industry recognition.

2. Product Range

A good supplier should offer a wide range of LED linear lenses to meet various project requirements. This includes different materials, beam angles, and specifications. A diverse product range allows lighting engineers to find the perfect lens for their specific needs.

3. Technical Support

Look for suppliers that provide technical support and guidance in selecting the right lenses for your applications. This can be invaluable in ensuring optimal performance. Technical support can include assistance with product selection, installation advice, and troubleshooting.

4. Certifications

Ensure that the supplier's products meet relevant industry standards and certifications. This is important for compliance and safety in lighting applications. Certifications can also indicate the quality and reliability of the products.

5. Pricing and Availability

Compare prices among different suppliers, but also consider the availability of products. A supplier with a good inventory can help you meet project deadlines. Timely availability of products is essential for maintaining project schedules and ensuring customer satisfaction.

Conclusion

Understanding the specifications of LED linear lenses is essential for lighting engineers to design effective and efficient lighting solutions. By considering parameters such as focal length, beam angle, material, and transmittance, engineers can select the right lenses for their projects. Additionally, choosing a reputable LED linear lens supplier can significantly impact the success of lighting designs. The right lenses not only enhance the functionality of lighting systems but also contribute to the overall aesthetic and energy efficiency of the spaces they illuminate.

Frequently Asked Questions

1. What is the importance of beam angle in LED linear lenses?

Answer: The beam angle determines how light is distributed from the lens. A narrow beam angle is suitable for focused lighting, while a wider angle is ideal for general illumination. Selecting the appropriate beam angle is crucial for achieving the desired lighting effect and ensuring that the light reaches the intended areas without excessive spill or shadowing.

2. How does the material of the lens affect its performance?

Answer: The material affects optical clarity, durability, and cost. Polycarbonate is more impact-resistant, making it suitable for high-traffic areas or outdoor applications, while acrylic lenses offer better optical properties, enhancing the quality of light output. The choice of material can also influence the overall weight and installation requirements of the lighting fixture.

3. What is the ideal CRI for LED lighting applications?

Answer: A CRI above 80 is generally preferred for applications where color accuracy is important, such as in retail or art galleries. In these environments, the ability to render colors faithfully can influence customer perceptions and enhance the overall experience. Lighting engineers should prioritize CRI when designing spaces where color fidelity is essential.

4. Why is thermal management important for LED linear lenses?

Answer: Effective thermal management prevents overheating, which can damage LED components and reduce their lifespan. Properly designed lenses help dissipate heat, ensuring that the LEDs operate within their optimal temperature range, thus maintaining performance and longevity.

5. How can I choose a reliable LED linear lens supplier?

Answer: Look for suppliers with a good reputation, a wide product range, technical support, relevant certifications, and competitive pricing. A reliable supplier will not only provide quality products but also assist in ensuring that the selected lenses meet the specific needs of your projects.