please click here:

https://www.sscontrolline.com/stainless-steel-coiled-tubing.html

Stainless steel coiled tubing has become a cornerstone technology in the oil and gas industry, offering unparalleled flexibility, durability, and efficiency for various well intervention and production operations. This article explores the manufacturing, technical specifications, applications, and benefits of stainless steel coiled tubing, emphasizing its critical role in enhancing oil and gas extraction and maintenance processes.

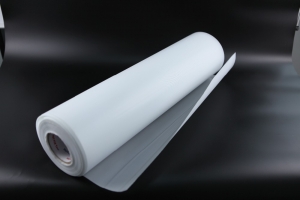

What Is Stainless Steel Coiled Tubing?

Stainless steel coiled tubing is a continuous length of stainless steel pipe that is wound into coils for easy handling and deployment. Unlike conventional jointed tubing, coiled tubing can be inserted into wells without the need for screwing multiple pipe segments together, allowing for faster and safer operations.

Manufacturing Process

Stainless steel coiled tubing is produced primarily in two forms: seamless and welded tubing. The process begins with hot extruded seamless pipes or welded strips that are cold reduced and shaped into long, continuous coils. Cold rolling improves surface finish and tensile strength, making the tubing suitable for high-pressure and corrosive environments typical in oil and gas wells. The coils can reach lengths up to 15,000 meters, especially for petroleum industry applications. Common stainless steel grades include 316L and duplex stainless steels like S32205 (2205), chosen for their corrosion resistance and mechanical strength.

The manufacturing steps include forming, welding (for welded tubing), heat treatment (annealing), and rigorous quality testing such as hydraulic pressure tests, hardness tests, and eddy current inspections to ensure safety and durability under extreme conditions.

Applications of Stainless Steel Coiled Tubing in Oil and Gas

Well Intervention and Maintenance

Coiled tubing is widely used for well intervention operations such as cleanouts, acidizing, fracturing, and matrix stimulation. Its flexibility allows it to navigate complex well geometries and deliver fluids or tools directly into the wellbore without halting production. This capability makes coiled tubing ideal for live well interventions, minimizing downtime and operational risks.

Drilling and Production

In some cases, coiled tubing is employed in drilling operations, especially for directional or horizontal wells where maneuverability is essential. It also serves as production tubing in depleted gas wells, enabling continuous extraction without the need for conventional tubing strings.

Chemical Injection and Pipeline Maintenance

Coiled tubing facilitates chemical injection for descaling and corrosion control within wells. It is also used in pipeline maintenance tasks such as cleaning, inspection, and leak repair, helping to extend the life of oil and gas infrastructure.

Enhanced Oil Recovery (EOR)

Techniques like hydraulic fracturing and acidizing are performed using coiled tubing to stimulate production and improve reservoir performance. Additionally, coiled tubing supports downhole installations, including electrical submersible pumps and zonal isolation tools like bridge plugs and packers.

Advantages of Stainless Steel Coiled Tubing

Flexibility and Versatility

The inherent flexibility of coiled tubing allows it to be coiled into compact rolls for transport and deployed into wells with complex geometries. This versatility enables access to remote or difficult-to-reach well sections that traditional tubing cannot reach.

Enhanced Operational Efficiency

Coiled tubing operations eliminate the need for frequent rig-ups and rig-downs, significantly reducing downtime. Continuous tubing length minimizes the risk of leaks and failures associated with threaded connections, ensuring uninterrupted operations.

Cost-Effectiveness

By reducing personnel requirements and speeding up deployment, coiled tubing lowers overall operational costs. The corrosion resistance and durability of stainless steel extend the tubing's service life, reducing maintenance and replacement expenses.

Safety Improvements

Reduced manual handling and rigging translate into fewer operational hazards. The robust stainless steel construction provides resistance against environmental and mechanical stresses, enhancing safety during well interventions.

High Pressure and Corrosion Resistance

Stainless steel coiled tubing withstands high pressures (up to 300 MPa) and temperatures (up to 500°C), making it suitable for harsh downhole environments. Its corrosion resistance protects against chemical attack from acids and other aggressive substances commonly encountered in oil and gas wells.

Technical Specifications and Standards

Stainless steel coiled tubing typically conforms to industry standards such as ASTM A269, ASTM A213, and ASTM A789. Common diameters range from 1/8 inch to 3/4 inch or customized sizes, with wall thickness adjusted to meet pressure and mechanical load requirements.

Grades like 316L are favored for their excellent corrosion resistance, while duplex stainless steels offer higher strength and pitting resistance for more demanding applications. Pressure ratings depend on tubing dimensions and material grade, with seamless tubing preferred for superior pressure tolerance.

Processing Methods: Hot Rolled vs. Cold Rolled

Hot Rolled Tubing

Hot rolling involves shaping stainless steel tubing at high temperatures, resulting in improved ductility and malleability but with a rougher surface finish. It is often used for economical mass production where structural integrity is prioritized over surface quality.

Cold Rolled Tubing

Cold rolling is performed at room temperature, enhancing surface smoothness and tensile strength. This process is preferred for applications requiring precision and high mechanical performance, such as instrumentation and hydraulic systems in oil and gas.

Industry Insights and Supplier Considerations

When selecting stainless steel coiled tubing, factors such as the specific application, environmental conditions, and mechanical requirements must be considered. Suppliers often provide extensive testing and certification to guarantee tubing quality and safety.

Leading manufacturers offer a range of tubing grades and dimensions, along with technical support to help customers choose the optimal product for their needs. The availability of long continuous coils reduces assembly time and improves operational efficiency on site.

Frequently Asked Questions (FAQs)

Q1: Why is stainless steel preferred for coiled tubing in oil and gas?

A1: Stainless steel offers excellent corrosion resistance, high strength, and durability, making it ideal for harsh downhole environments where chemical exposure and high pressures are common.

Q2: What are the main applications of coiled tubing in oil and gas?

A2: Coiled tubing is used for well intervention, drilling, production enhancement, chemical injection, pipeline maintenance, and enhanced oil recovery techniques.

Q3: How does coiled tubing improve operational efficiency?

A3: It reduces downtime by eliminating the need for jointed tubing connections and rigging operations, allowing continuous deployment and live well interventions.

Q4: What are the differences between seamless and welded stainless steel coiled tubing?

A4: Seamless tubing is manufactured from extruded pipe and offers superior pressure resistance and reliability, while welded tubing is formed from rolled strips welded along the seam, typically used where cost efficiency is prioritized.

Q5: What pressure and temperature ratings can stainless steel coiled tubing withstand?

A5: Depending on grade and dimensions, stainless steel coiled tubing can handle pressures up to 300 MPa and temperatures up to 500°C, suitable for demanding oil and gas applications.

Article Summary

Stainless steel coiled tubing is a vital technology in the oil and gas industry, offering flexibility, durability, and corrosion resistance for well intervention, drilling, and production operations. Manufactured in seamless and welded forms, it withstands high pressures and harsh environments. Its advantages include enhanced efficiency, cost savings, and improved safety, making it indispensable for modern oilfield applications.