please click here:

https://www.everhealgroup.com/bfs-machine-manufacturer.html

Introduction to Pharmaceutical Production Lines

The pharmaceutical industry is built on precision, consistency, and compliance with strict regulations. A pharmaceutical production line is the backbone of drug manufacturing, transforming raw materials into finished medicines ready for distribution. From tablets and capsules to injectables and creams, production lines integrate technology, quality control, and automation to meet growing global demand while ensuring safety.

As medicine evolves with biotechnology, personalized treatment, and stricter quality standards, production lines are adapting with advanced equipment, digital integration, and smart manufacturing practices. Understanding how these systems operate, their components, and their advantages is essential for both manufacturers and healthcare providers.

The Core Components of a Pharmaceutical Production Line

Every pharmaceutical production line includes interconnected stages that ensure efficiency and compliance. Key components include:

Raw Material Handling

-

Secure storage of active pharmaceutical ingredients (APIs) and excipients

-

Controlled humidity and temperature conditions

-

Automated dosing to minimize contamination

Mixing and Blending

-

Homogeneous blending of powders or liquids

-

High-shear mixers to ensure consistent particle size

-

Precision control to prevent batch variation

Granulation and Drying

-

Wet or dry granulation processes to improve compressibility

-

Fluid bed dryers and vacuum dryers for moisture control

Tablet Compression and Encapsulation

-

High-speed tablet presses for uniform dosage

-

Encapsulation machines for hard or soft gelatin capsules

Coating and Finishing

-

Film and sugar coating systems

-

Controlled-release coating technologies

Packaging

-

Blister packs, bottles, or sachets

-

Tamper-evident seals and serialization for anti-counterfeiting

The Role of Automation in Modern Production Lines

Automation has redefined pharmaceutical production by enhancing speed, accuracy, and traceability. Robotics handle repetitive tasks such as filling, labeling, and packaging, reducing human error. Automated systems also ensure compliance with Good Manufacturing Practices (GMP).

Benefits of automation include:

-

Reduced risk of contamination

-

Consistent batch quality

-

Real-time monitoring and data analytics

-

Cost savings through minimized labor

Comparison: Traditional vs. Modern Pharmaceutical Production Lines

| Aspect | Traditional Production Line | Modern Production Line |

|---|---|---|

| Level of Automation | Minimal, reliant on manual labor | High, with robotics and AI integration |

| Quality Control | Sample-based testing | Continuous in-line monitoring |

| Flexibility | Limited to large batch production | Adaptable to small batches and personalized meds |

| Efficiency | Lower throughput, higher downtime | High throughput, optimized workflows |

| Compliance | Manual documentation | Digital records with traceability |

Regulatory Compliance in Pharmaceutical Manufacturing

Pharmaceutical companies must comply with strict regulatory frameworks such as FDA, EMA, and WHO standards. Production lines are designed to align with GMP principles, which ensure product safety, efficacy, and quality.

Important compliance aspects include:

-

Validated equipment and processes

-

Documentation of every step

-

Environmental monitoring in cleanrooms

-

Serialization and track-and-trace systems

Innovations Driving the Future of Pharmaceutical Production Lines

Continuous Manufacturing

Unlike traditional batch processes, continuous manufacturing keeps materials moving through the production line without interruption. This reduces costs, shortens production time, and enhances product quality.

Pharma 4.0 and Smart Manufacturing

Integration of Internet of Things (IoT), Artificial Intelligence (AI), and digital twins allows predictive maintenance, real-time monitoring, and data-driven decision-making.

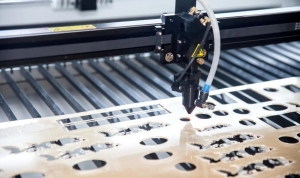

Personalized Medicine Production

Future production lines must handle smaller, more customized batches. 3D printing of drugs is being explored to enable personalized dosages.

Sustainability in Manufacturing

Eco-friendly practices are becoming a priority, such as energy-efficient equipment, green solvents, and waste reduction technologies.

Challenges in Pharmaceutical Production Lines

Despite advancements, companies face challenges such as:

-

High capital investment for automation and compliance

-

Maintaining flexibility while meeting mass demand

-

Managing supply chain disruptions for raw materials

-

Skilled workforce shortages in handling advanced machinery

Strategies for Optimizing a Pharmaceutical Production Line

To remain competitive, manufacturers must focus on:

-

Investing in automation and digital technologies

-

Training staff to operate and maintain modern equipment

-

Implementing predictive maintenance to reduce downtime

-

Leveraging data analytics for process optimization

-

Building flexible systems to handle diverse product portfolios

Frequently Asked Questions

1. What is a pharmaceutical production line?

A pharmaceutical production line is a sequence of interconnected equipment and processes that transform raw materials into finished medicines under strict regulatory compliance.

2. Why is automation important in pharmaceutical production?

Automation reduces contamination risks, enhances efficiency, and ensures consistent product quality while minimizing reliance on manual labor.

3. What is the difference between batch and continuous manufacturing?

Batch manufacturing processes one batch at a time, while continuous manufacturing maintains a constant flow of materials, improving efficiency and reducing costs.

4. How do production lines ensure compliance with regulations?

They incorporate validated equipment, digital documentation, environmental controls, and real-time monitoring to meet global GMP standards.

5. What future trends will shape pharmaceutical production lines?

Trends include smart manufacturing with AI and IoT, personalized medicine production, sustainability initiatives, and widespread adoption of continuous manufacturing.

Summary

Pharmaceutical production lines form the backbone of modern drug manufacturing, integrating automation, quality control, and regulatory compliance. With innovations like continuous manufacturing, AI-driven monitoring, and sustainable practices, these systems are evolving to meet global healthcare demands efficiently.