please click here:

https://www.xdfans.com/frameless-fan-supplier.html

The global demand for compact, energy-efficient cooling solutions has propelled OEM frameless fan manufacturers into a pivotal role across industries. These specialized fans, characterized by their space-saving designs and high-performance capabilities, are revolutionizing thermal management in electronics, automotive systems, aerospace technology, and industrial machinery. With the market projected to grow from USD 73.3 billion in 2024 to USD 110.1 billion by 2032 at a 5.2% CAGR, manufacturers are innovating with advanced materials, smart control systems, and customized solutions to meet diverse application requirements.

Applications of Frameless Fans Across Industries

Electronics Cooling Systems

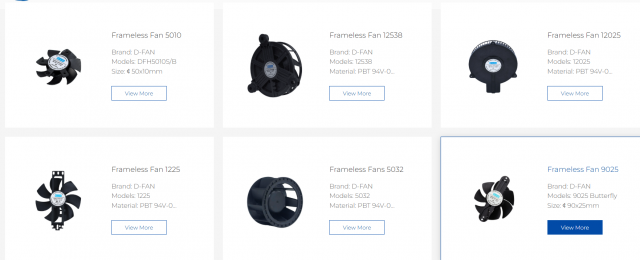

Modern consumer electronics rely on 30x10mm and 70mm frameless fans to prevent overheating in smartphones, laptops, and gaming consoles. Their frameless construction allows direct mounting on circuit boards, optimizing space utilization in devices like graphics cards and SSD storage units. In server farms, larger 200mm variants provide silent yet powerful airflow management for high-density computing environments.

Automotive Thermal Regulation

Electric vehicle manufacturers integrate frameless centrifugal blowers in battery cooling systems and cabin climate controls. These fans operate at temperatures ranging from -35°C to 90°C, ensuring reliable performance in extreme conditions. A leading Chinese automaker recently implemented 60mm frameless units in their EV powertrains, reducing thermal management system weight by 40% compared to traditional fans.

Aerospace and Defense Implementations

Avionics cooling systems utilize military-grade frameless fans with IP67 dust/moisture protection and MIL-Spec salt fog resistance. These units maintain optimal temperatures for flight control computers and radar systems while withstanding intense vibration profiles. The latest fighter jet prototypes feature titanium-alloy frameless fans that reduce component weight by 28% compared to conventional cooling systems.

HVAC and Building Automation

Smart building systems incorporate frameless fan arrays in ductless ventilation units, with PWM-controlled 120mm models achieving 65% energy savings over traditional AC fans. Modular designs enable seamless integration into IoT-enabled climate control networks, with some manufacturers offering API-programmable units for automated airflow optimization.

Advanced Manufacturing Processes

Material Selection and Component Fabrication

High-performance polymers like PBT (Polybutylene Terephthalate) dominate impeller production due to their UL94V-0 flame resistance and dimensional stability. Stainless steel shafts with diamond-like carbon (DLC) coatings minimize friction in high-RPM applications. The injection molding process for 70mm fan housings now incorporates AI-driven quality monitoring, reducing material waste by 18%.

Automated Assembly Techniques

Robotic assembly lines handle precision tasks like rotor balancing and magnetic circuit alignment. Vision systems verify blade tip clearances within 0.05mm tolerances, while laser welding creates permanent bonds between motor stators and mounting plates. A recent factory tour video revealed how automated test stations simulate 10,000 hours of operation in 72-hour stress tests.

Quality Control Protocols

Manufacturers implement three-stage testing regimens:

-

Aerodynamic performance verification using ISO 5801-compliant wind tunnels

-

Acoustic profiling in anechoic chambers measuring down to 15 dBA

-

Environmental stress testing across temperature (-40°C to 125°C) and humidity (5-95% RH) extremes

Market Dynamics and Growth Drivers

Regional Production Hubs

China's Dongguan province hosts over 60% of global frameless fan production capacity, with specialized clusters for automotive-grade (Guangzhou) and micro-fan (Shenzhen) manufacturing. European manufacturers lead in aerospace-certified units, while North American factories dominate IoT-enabled smart fan production.

Technological Advancements

Brushless DC motor designs now achieve 85% energy efficiency ratings, with some models incorporating regenerative braking systems. The emergence of graphene-coated bearings has extended operational lifespans to 100,000+ hours in continuous duty applications.

Selecting OEM Manufacturing Partners

Customization Capabilities

Leading manufacturers offer:

-

Voltage options from 5V to 480V AC/DC

-

Custom blade geometries optimized for specific airflow patterns

-

Embedded sensors for real-time RPM monitoring

-

EMI/RFI shielding for medical equipment applications

Certification Requirements

Reputable suppliers maintain:

-

ISO 9001:2015 quality management systems

-

UL 507 safety certifications

-

RoHS and REACH compliance documentation

-

ITAR registration for defense applications

Industry Case Studies

Pelonis Technologies' Smart Fan Series

The PLB07010B12HH-A model combines PWM control with IoT connectivity, enabling predictive maintenance through cloud-based analytics. Its frameless design reduces axial length by 30% compared to traditional 70mm fans.

D-Fan's Automotive Solutions

D-Fan's 3010 frameless series features patented vapor deposition coatings that withstand automotive coolant exposure. Their production process integrates blockchain-tracked quality documentation for Tier 1 suppliers.

Frequently Asked Questions

Q1: What are the primary advantages of frameless fans over traditional designs?

Frameless fans offer 40-60% space savings, 25% lower power consumption, and 15 dB noise reduction through eliminated frame resonance.

Q2: How do temperature ranges vary between standard and custom units?

Standard models operate from -10°C to 70°C, while customized versions withstand -35°C to 125°C for aerospace applications.

Q3: What certifications should medical device manufacturers require?

ISO 13485 quality systems and IEC 60601-1 electrical safety certifications are mandatory for medical cooling applications.

Q4: How are smart features integrated into modern frameless fans?

Manufacturers embed MEMS sensors and CAN bus interfaces for real-time thermal monitoring and system integration.

Q5: What customization options exist for unusual form factors?

OEMs can request oval, hexagonal, or triangular footprints with thicknesses from 5mm to 150mm.

Summary: This comprehensive analysis examines the OEM frameless fan industry, detailing applications from consumer electronics to aerospace systems. It explores advanced manufacturing techniques using PBT polymers and automated assembly, while analyzing market growth projections reaching $110B by 2032. The guide assists buyers in evaluating manufacturer capabilities, highlighting essential certifications and customization options. Case studies demonstrate real-world implementations, with FAQs addressing key technical considerations.