Introduction

In the realm of modern lighting technology, maximizing light efficiency is a critical goal. One of the most innovative solutions to achieve this is through the use of extruded linear lenses. These lenses are designed to enhance the performance of light sources, particularly LEDs, by optimizing light distribution and minimizing losses. This article delves into the science behind extruded linear lenses, their manufacturing processes, and their applications in various lighting scenarios. By understanding the intricacies of these lenses, we can appreciate their role in advancing energy-efficient lighting solutions.

Understanding Extruded Linear Lenses

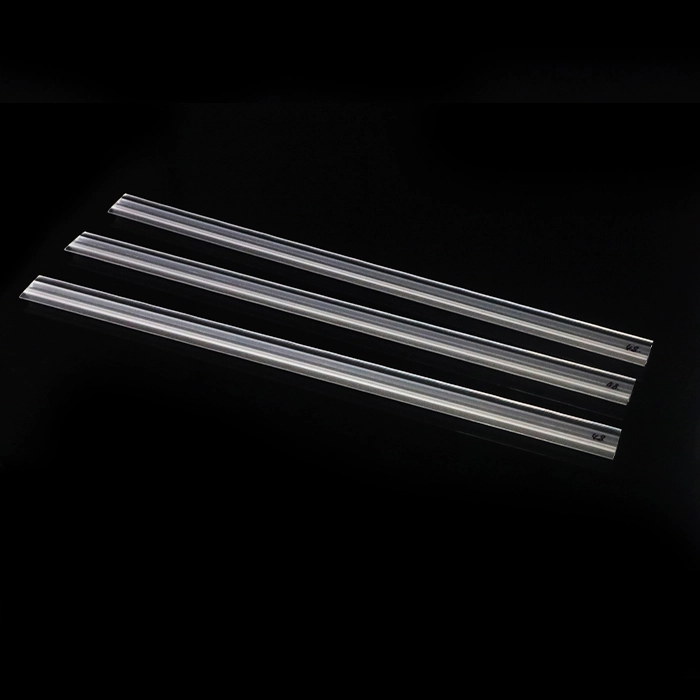

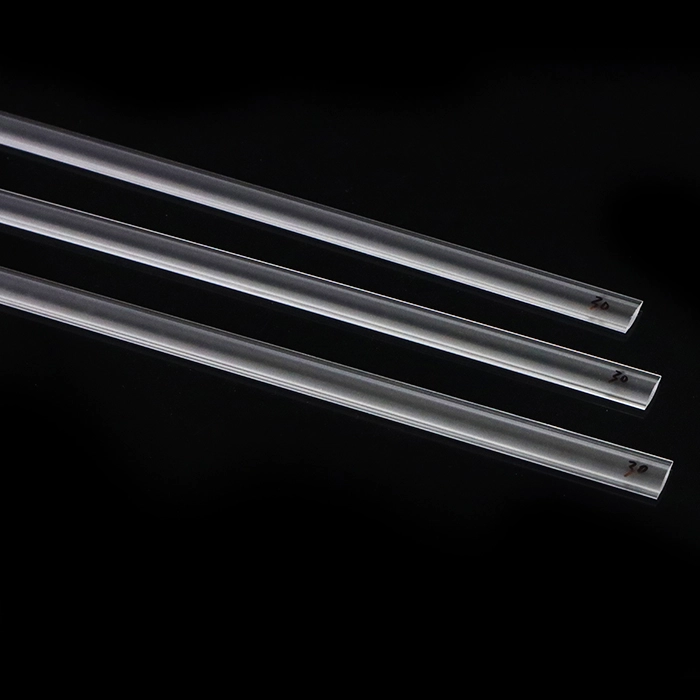

What Are Extruded Linear Lenses?

Extruded linear lenses are optical components made from thermoplastic materials, typically acrylic or polycarbonate, that are shaped through an extrusion process. This method allows for the production of lenses with precise geometries and optical properties, making them ideal for a variety of lighting applications. The extrusion process involves forcing molten material through a die to create continuous lengths of lens material, which can then be cut to size. This manufacturing technique not only ensures uniformity in lens production but also allows for customization in terms of length, thickness, and optical characteristics, catering to specific lighting needs.

The Importance of Light Efficiency

Light efficiency refers to the ability of a lighting system to convert electrical energy into visible light. High light efficiency is essential for reducing energy consumption and minimizing environmental impact. Extruded linear lenses play a pivotal role in enhancing light efficiency by directing and diffusing light effectively, ensuring that more of the emitted light reaches the intended area. This is particularly important in commercial and industrial settings, where lighting accounts for a significant portion of energy costs. By improving light efficiency, businesses can lower their energy bills and contribute to sustainability efforts, making extruded linear lenses a valuable investment.

The Science Behind Light Efficiency

Optical Principles

The effectiveness of extruded linear lenses is rooted in several optical principles:

1. Refraction: When light passes through a lens, it bends due to the change in medium. The degree of bending depends on the lens shape and the refractive index of the material. By designing lenses with specific curvatures, manufacturers can control the direction of light rays. This control is crucial for applications requiring precise light placement, such as in spotlighting or task lighting.

2. Total Internal Reflection: This phenomenon occurs when light hits the boundary of a medium at a steep angle, causing it to reflect entirely within the medium. Extruded linear lenses can be designed to maximize total internal reflection, thereby increasing the amount of light that is directed forward. This property is particularly beneficial in applications where maximizing light output is essential, such as in high-efficiency LED fixtures.

3. Diffusion: Some extruded linear lenses incorporate microstructures that scatter light, creating a more uniform light distribution. This is particularly useful in applications where glare reduction and even illumination are desired. By diffusing light, these lenses help create a comfortable visual environment, reducing eye strain and enhancing the overall aesthetic of the space.

Material Selection

The choice of material for extruded linear lenses significantly impacts their performance. Common materials include:

- Acrylic (PMMA): Known for its excellent optical clarity and UV resistance, acrylic is lightweight and easy to mold, making it a popular choice for extruded lenses. Its high light transmission properties ensure that minimal light is lost as it passes through the lens, making it ideal for applications where brightness is critical.

- Polycarbonate: This material is more impact-resistant than acrylic and is often used in applications where durability is crucial. Polycarbonate lenses can withstand harsh environmental conditions, making them suitable for outdoor lighting applications. Additionally, they offer good optical clarity and can be treated with coatings to enhance their performance further.

Design Considerations

When designing extruded linear lenses, several factors must be considered to maximize light efficiency:

- Lens Shape: The geometry of the lens affects how light is refracted and distributed. Common shapes include cylindrical, prismatic, and aspheric designs. Each shape serves a specific purpose; for instance, prismatic lenses can redirect light at specific angles, making them ideal for applications requiring focused beams.

- Surface Finish: The surface texture of the lens can influence light transmission and reflection. Smooth surfaces tend to minimize scattering, while textured surfaces can enhance diffusion. Manufacturers often experiment with different finishes to achieve the desired optical effects, balancing clarity and diffusion based on the application.

- Coatings: Anti-reflective coatings can be applied to reduce losses due to reflection at the lens surface, further improving light efficiency. These coatings are particularly important in high-performance applications where every lumen counts, such as in commercial lighting fixtures.

Manufacturing Extruded Linear Lenses

The Extrusion Process

The manufacturing of extruded linear lenses involves several key steps:

1. Material Preparation: Raw thermoplastic materials are fed into an extruder, where they are heated until molten. This step is critical, as the temperature must be carefully controlled to ensure the material flows smoothly without degrading.

2. Extrusion: The molten material is forced through a die that shapes it into the desired lens profile. This process can produce continuous lengths of lens material, allowing for efficient production and minimal waste.

3. Cooling and Solidification: As the extruded material exits the die, it is cooled to solidify the lens shape. Cooling methods can vary, with some manufacturers using air cooling while others may employ water baths to achieve the desired cooling rate.

4. Cutting and Finishing: The continuous lens material is cut into specified lengths, and any necessary finishing processes, such as polishing or coating, are applied. This final step ensures that the lenses meet the required optical standards and are ready for installation.

Quality Control

Quality control is essential in the production of extruded linear lenses. Manufacturers conduct rigorous testing to ensure that the lenses meet optical performance standards. This includes measuring light transmission, refractive index, and surface quality. Advanced optical testing equipment is often employed to assess the lenses' performance under various conditions, ensuring that they will perform as expected in real-world applications.

Applications of Extruded Linear Lenses

Extruded linear lenses are used in a wide range of applications, including:

1. Architectural Lighting

In architectural lighting, extruded linear lenses are employed to create visually appealing light fixtures that enhance the aesthetics of buildings. They provide uniform illumination and can be designed to minimize glare. This is particularly important in public spaces where lighting must be both functional and visually pleasing.

2. Retail and Commercial Spaces

In retail environments, effective lighting is crucial for showcasing products. Extruded linear lenses help create bright, inviting spaces while ensuring that light is evenly distributed across displays. This not only enhances the shopping experience but also encourages customer engagement and increases sales.

3. Industrial Lighting

In warehouses and manufacturing facilities, extruded linear lenses are used in high-bay lighting systems. They maximize light output while minimizing energy consumption, contributing to overall operational efficiency. By providing bright, even lighting, these lenses help improve safety and productivity in industrial settings.

4. Outdoor Lighting

For outdoor applications, such as streetlights and parking lot illumination, extruded linear lenses are designed to withstand harsh weather conditions while providing optimal light distribution for safety and visibility. Their durability and performance make them ideal for ensuring that outdoor areas are well-lit and secure.

5. Automotive Lighting

In the automotive industry, extruded linear lenses are used in headlights and taillights. Their ability to focus and diffuse light enhances visibility and safety for drivers. As automotive technology evolves, these lenses are also being integrated into advanced lighting systems, such as adaptive headlights that adjust based on driving conditions.

Future Trends in Extruded Linear Lens Technology

As technology advances, the future of extruded linear lenses looks promising. Key trends include:

1. Smart Lighting Integration

With the rise of smart lighting systems, extruded linear lenses are being designed to work seamlessly with sensors and control systems. This integration allows for dynamic lighting adjustments based on occupancy and ambient light levels. Such systems can significantly enhance energy efficiency and user comfort, adapting to the needs of the environment in real-time.

2. Sustainable Materials

There is a growing emphasis on sustainability in manufacturing. Future extruded linear lenses may be made from biodegradable or recycled materials, reducing their environmental impact. This shift towards sustainable practices aligns with global efforts to minimize waste and promote eco-friendly products.

3. Enhanced Optical Designs

Advancements in optical design software are enabling manufacturers to create more complex lens geometries that optimize light efficiency even further. This includes the use of computational modeling to predict light behavior through lenses. As a result, manufacturers can develop innovative designs that push the boundaries of traditional lens technology.

Conclusion

Extruded linear lenses represent a significant advancement in lighting technology, offering solutions that maximize light efficiency across various applications. By understanding the science behind these lenses, manufacturers can continue to innovate and improve lighting systems, contributing to energy savings and enhanced visual experiences. As the demand for efficient and sustainable lighting solutions grows, extruded linear lenses will play a crucial role in shaping the future of illumination.

Frequently Asked Questions

1. What are extruded linear lenses made of?

Extruded linear lenses are typically made from thermoplastic materials such as acrylic (PMMA) or polycarbonate, chosen for their optical clarity and durability.

2. How do extruded linear lenses improve light efficiency?

These lenses improve light efficiency by directing and diffusing light effectively, minimizing losses due to reflection and scattering.

3. What applications benefit from extruded linear lenses?

Applications include architectural lighting, retail spaces, industrial lighting, outdoor lighting, and automotive lighting.

4. What is the extrusion process for manufacturing lenses?

The extrusion process involves heating thermoplastic materials, forcing them through a die to create lens shapes, cooling them, and then cutting them to size.

5. What future trends are expected in extruded linear lens technology?

Future trends include smart lighting integration, the use of sustainable materials, and enhanced optical designs for improved light efficiency.