Choosing the right CNC milling service provider is crucial for the success of your manufacturing projects. CNC (Computer Numerical Control) milling is a precision machining process that uses computer-controlled machines to create parts and components from various materials. The right service provider can significantly impact the quality, efficiency, and cost-effectiveness of your production. This article will guide you through the essential factors to consider when selecting a CNC milling service provider.

Understanding CNC Milling Services

What is CNC Milling?

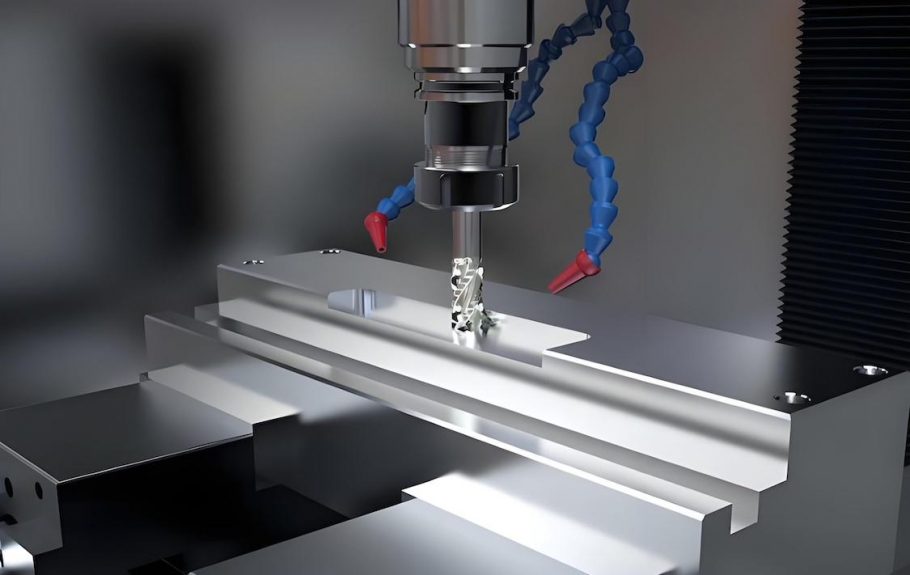

CNC milling is a subtractive manufacturing process that involves removing material from a solid block to create a desired shape. This process is highly precise and can produce complex geometries that are difficult to achieve with traditional machining methods. CNC milling machines can work with various materials, including metals, plastics, and composites, making them versatile for different applications. The precision of CNC milling allows for tight tolerances, which is essential in industries where even minor deviations can lead to significant issues in functionality or safety.

Applications of CNC Milling

CNC milling is used in various industries, including aerospace, automotive, medical, and consumer goods. Common applications include:

Prototype Development: Rapid prototyping allows for quick iterations and testing of designs. This is particularly valuable in industries where time-to-market is critical, enabling companies to refine their products based on real-world feedback before full-scale production.

Production Parts: High-volume production of components with tight tolerances. CNC milling can produce thousands of identical parts with consistent quality, making it ideal for mass production scenarios.

Custom Parts: One-off or low-volume production of specialized components tailored to specific needs. This flexibility allows businesses to meet unique customer demands or create specialized tools and fixtures that enhance their operational capabilities.

Key Factors to Consider When Selecting a CNC Milling Service Provider

Experience and Expertise

One of the first things to evaluate is the experience and expertise of the service provider. Look for a company with a proven track record in CNC milling. Experienced providers are more likely to understand the nuances of different materials and machining processes, which can lead to better quality and efficiency. Their familiarity with common challenges and solutions can also help in troubleshooting potential issues before they escalate.

Industry-Specific Knowledge

Different industries have unique requirements and standards. A provider with experience in your specific industry will be better equipped to meet your needs. They will be familiar with the regulatory requirements and quality standards that apply to your project. This knowledge can streamline the production process and ensure compliance with industry regulations, ultimately saving time and resources.

Equipment and Technology

The type of equipment and technology used by the CNC milling service provider is critical. Advanced machinery can offer higher precision, faster production times, and the ability to work with a wider range of materials. Investing in state-of-the-art technology can also enhance the provider's capabilities, allowing them to take on more complex projects.

Types of CNC Machines

Consider the types of CNC milling machines the provider has. For example, 3-axis machines are suitable for simpler parts, while 5-axis machines can handle more complex geometries. The availability of specialized equipment, such as high-speed machining or multi-tasking machines, can also be a significant advantage. Providers with diverse machinery can offer more options and flexibility in meeting your specific project requirements.

Quality Assurance Processes

Quality assurance is vital in CNC milling. Inquire about the provider's quality control processes. A reputable service provider will have established protocols to ensure that every part meets the required specifications. This may include regular inspections, testing, and adherence to industry standards.

Certifications and Standards

Check if the provider holds relevant certifications, such as ISO 9001. These certifications indicate that the company adheres to international quality management standards, which can give you confidence in their capabilities. Certifications also demonstrate a commitment to continuous improvement and customer satisfaction, which are essential for long-term partnerships.

Lead Times and Flexibility

Understanding the lead times for production is essential for planning your project. Ask potential providers about their typical turnaround times and their ability to accommodate rush orders if necessary. Flexibility in scheduling can be a significant advantage, especially if your project timelines are tight. A provider that can adapt to changing demands can help you stay on track and meet critical deadlines.

Cost Considerations

While cost should not be the sole determining factor, it is essential to understand the pricing structure of the CNC milling service provider. Request detailed quotes that outline all costs associated with the project, including setup fees, material costs, and any additional charges. Transparency in pricing can help you avoid unexpected expenses later in the project.

Value vs. Price

Consider the value you are getting for the price. A lower-cost provider may not always deliver the best quality or service. Evaluate the overall value, including quality, reliability, and customer support. Sometimes, investing a bit more upfront can lead to significant savings in the long run through reduced rework and improved product quality.

Communication and Customer Service

Effective communication is crucial throughout the manufacturing process. Choose a provider that is responsive and willing to collaborate with you. Good customer service can make a significant difference in resolving issues and ensuring that your project runs smoothly. A provider that prioritizes communication can help you stay informed about project progress and any potential challenges.

Project Management

Inquire about the project management practices of the provider. A well-organized approach to managing projects can lead to better outcomes and fewer delays. Providers that utilize project management tools and methodologies can enhance efficiency and ensure that all team members are aligned on project goals and timelines.

Material Capabilities

Different CNC milling service providers may specialize in specific materials. Ensure that the provider you choose has experience working with the materials required for your project. This expertise can impact the quality and performance of the final product. Providers familiar with the properties and machining characteristics of various materials can offer valuable insights and recommendations.

Material Sourcing

Ask about the provider's material sourcing practices. Reliable suppliers will have access to high-quality materials and can provide recommendations based on your project requirements. Understanding the provider's supply chain can also help you assess their ability to meet your material needs consistently.

Post-Processing Services

Consider whether the CNC milling service provider offers post-processing services, such as finishing, assembly, or packaging. These additional services can save you time and effort, allowing for a more streamlined production process. Providers that offer comprehensive solutions can help you reduce the number of vendors you need to manage, simplifying your supply chain.

Location and Logistics

The location of the CNC milling service provider can impact shipping costs and lead times. Consider whether you prefer a local provider for easier communication and logistics or if you are open to working with a provider located further away. Proximity can facilitate quicker turnaround times and reduce shipping costs, while remote providers may offer specialized expertise.

Shipping and Delivery

Inquire about the provider's shipping and delivery options. Understanding their logistics capabilities can help you plan for the timely arrival of your parts. A provider with a reliable shipping process can help you avoid delays that could impact your production schedule.

Conclusion

Selecting the right CNC milling service provider is a critical decision that can influence the success of your manufacturing projects. By considering factors such as experience, equipment, quality assurance, lead times, cost, communication, material capabilities, and logistics, you can make an informed choice that aligns with your project needs. Take the time to research and evaluate potential providers thoroughly, as this investment in due diligence will pay off in the long run with high-quality results and successful project outcomes. A well-chosen partner can enhance your manufacturing capabilities and contribute to your overall business success.

Frequently Asked Questions regarding Custom CNC Milling Service

1. What should I look for in a CNC milling service provider's experience?

When evaluating a provider's experience, consider their years in business, the variety of projects they have completed, and their expertise in your specific industry. Look for case studies or testimonials that demonstrate their ability to handle projects similar to yours.

2. How can I assess the quality of a CNC milling service provider?

You can assess quality by reviewing their quality assurance processes, certifications (like ISO 9001), and customer feedback. Request samples of their work to evaluate the precision and finish of their machined parts.

3. What types of CNC milling machines should a good provider have?

A good CNC milling service provider should have a range of machines, including 3-axis and 5-axis milling machines. The availability of advanced equipment, such as high-speed machining and multi-tasking machines, is also beneficial for handling complex projects.

4. How important is communication during the CNC milling process?

Communication is crucial throughout the CNC milling process. A provider that maintains open lines of communication can quickly address any issues, provide updates on project status, and ensure that your specifications are met accurately.

5. What are the typical lead times for CNC milling projects?

Lead times can vary based on the complexity of the project, the provider's workload, and the materials used. It's essential to discuss expected lead times upfront and inquire about the provider's ability to accommodate rush orders if needed.