Sheet metal fabrication is a critical process in various industries, including automotive, aerospace, and construction. Ensuring quality and precision in this process is essential for producing components that meet stringent specifications and performance standards. This article explores the key aspects of achieving high-quality sheet metal fabrication, including design considerations, material selection, fabrication techniques, quality control measures, and the importance of skilled labor.

Understanding Sheet Metal Fabrication

Sheet metal fabrication involves transforming flat sheets of metal into specific shapes and sizes through various processes such as cutting, bending, and assembling. The materials commonly used include aluminum, steel, copper, and brass, each offering unique properties suitable for different applications. The versatility of sheet metal allows it to be used in a wide range of products, from simple brackets to complex enclosures, making it a fundamental aspect of modern manufacturing.

The Importance of Quality and Precision

Quality and precision in sheet metal fabrication are vital for several reasons. First, the performance of components is directly linked to their accuracy. Parts that do not fit together correctly can lead to mechanical failures or inefficiencies in the final product. Second, durability is a key consideration; high-quality fabrication ensures that parts can withstand operational stresses, reducing the likelihood of premature failure. Lastly, cost efficiency plays a significant role; reducing waste and rework through precise fabrication saves time and resources, ultimately leading to higher profitability for manufacturers.

Design Considerations

The design phase is crucial in ensuring the quality and precision of fabricated sheet metal parts. Effective design can minimize errors and enhance manufacturability. A well-thought-out design not only considers the aesthetic aspects but also the functional requirements of the component.

Utilizing CAD Software

Computer-Aided Design (CAD) software allows engineers to create detailed models of the components. These models can be tested for fit and function before fabrication begins, reducing the likelihood of errors. Advanced CAD tools also enable simulations that can predict how the material will behave during fabrication, helping to identify potential issues early in the design process. This proactive approach can save significant time and resources by preventing costly mistakes.

Design for Manufacturability (DFM)

Incorporating Design for Manufacturability (DFM) principles helps streamline the fabrication process. This includes simplifying designs, minimizing the number of parts, and ensuring that components can be easily assembled. DFM encourages designers to think about the manufacturing process during the design phase, which can lead to innovations that enhance efficiency and reduce costs. By focusing on manufacturability, companies can improve their production timelines and overall product quality.

Tolerances and Specifications

Defining clear tolerances and specifications is essential. Tolerances dictate the allowable variations in dimensions, which directly impact the fit and function of the final product. Establishing precise specifications helps ensure that all components meet the required standards, facilitating easier assembly and reducing the risk of defects. Clear communication of these tolerances to all stakeholders involved in the fabrication process is crucial for maintaining quality.

Material Selection

Choosing the right material is fundamental to achieving quality in sheet metal fabrication. Different materials have varying properties that affect their workability and performance. The selection process should consider not only the mechanical properties but also the environmental conditions the final product will face.

Common Materials Used

Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for applications requiring weight savings, such as in the aerospace industry. Its excellent strength-to-weight ratio makes it a popular choice for components that need to be both strong and lightweight.

Stainless Steel: Known for its strength and corrosion resistance, stainless steel is suitable for harsh environments, such as in food processing or chemical manufacturing. Its durability and aesthetic appeal also make it a preferred choice for architectural applications.

Mild Steel: Cost-effective and easy to work with, mild steel is commonly used in general fabrication. It is versatile and can be easily welded, making it suitable for a wide range of applications, from structural components to automotive parts.

Material Properties

Understanding the properties of materials, such as tensile strength, ductility, and thermal conductivity, helps in selecting the right material for specific applications. For instance, materials with high tensile strength are essential for components that will experience significant loads, while ductile materials are preferred for parts that require bending or forming. Additionally, considering factors like thermal expansion and conductivity can influence the performance of the final product in its intended environment.

Fabrication Techniques

The choice of fabrication techniques significantly influences the quality and precision of the final product. Various methods are employed, each with its advantages and limitations. Selecting the appropriate technique depends on the specific requirements of the project, including material type, thickness, and desired tolerances.

Cutting Techniques

Laser Cutting: Provides high precision and clean edges, suitable for intricate designs. Laser cutting is particularly effective for complex shapes and can handle a variety of materials with minimal kerf loss, making it an efficient choice for high-precision applications.

Waterjet Cutting: Uses high-pressure water to cut materials, ideal for thicker sheets and sensitive materials. This method does not introduce heat into the material, preventing warping and maintaining the integrity of the material properties.

Plasma Cutting: Effective for cutting through thick metals quickly, though it may produce rougher edges. Plasma cutting is often used in industrial applications where speed is essential, and post-processing can be applied to achieve the desired finish.

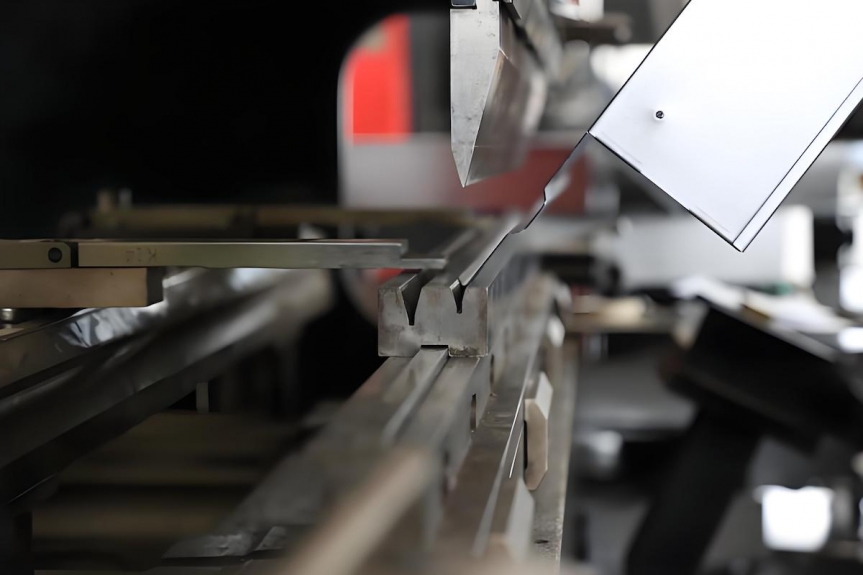

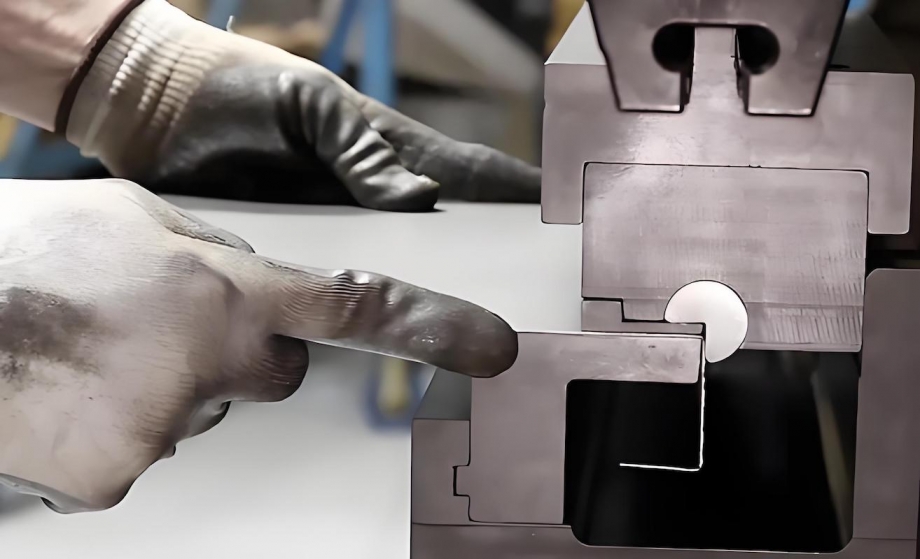

Bending Techniques

Bending is a common process in sheet metal fabrication. The accuracy of bends is crucial for ensuring that parts fit together correctly. The choice of bending technique can significantly affect the final product's quality.

Press Brake Bending: A widely used method that allows for precise control over the bending angle and depth. Press brakes can accommodate various thicknesses and materials, making them versatile for different applications.

Roll Bending: Suitable for creating curves and cylindrical shapes, often used in structural applications. Roll bending is particularly useful for producing large components, such as pipes and frames, where uniform curvature is required.

Welding and Assembly

Welding is often required to join multiple components. The quality of the welds is critical for the integrity of the final assembly. Different welding techniques can be employed based on the materials and thicknesses involved.

TIG Welding: Provides high-quality welds with excellent control, ideal for thin materials. This method is known for its precision and is often used in applications where aesthetics and strength are paramount.

MIG Welding: Faster and easier to learn, MIG welding is suitable for thicker materials and production environments. It allows for continuous welding, making it efficient for high-volume production runs.

Quality Control Measures

Implementing robust quality control measures is essential for ensuring that fabricated components meet the required standards. Quality control should be integrated throughout the fabrication process, from design to final inspection.

Inspection Techniques

Regular inspections throughout the fabrication process help identify defects early. Common inspection methods include:

Visual Inspection: Checking for surface defects and overall appearance. This initial inspection can catch obvious flaws that may affect the product's functionality.

Dimensional Inspection: Using calipers and gauges to verify that parts meet specified dimensions. This step is crucial for ensuring that components will fit together as intended.

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspection to detect internal flaws without damaging the part. NDT methods are essential for critical applications where internal integrity is as important as surface quality.

Statistical Process Control (SPC)

Statistical Process Control (SPC) involves monitoring the fabrication process using statistical methods to identify variations and trends. This proactive approach helps maintain consistent quality. By analyzing data collected during production, manufacturers can make informed decisions to improve processes and reduce variability, ultimately leading to higher quality products.

The Role of Skilled Labor

Skilled labor is a critical component of quality sheet metal fabrication. Experienced fabricators understand the nuances of the materials and processes, enabling them to produce high-quality components. Their expertise is invaluable in troubleshooting issues that may arise during fabrication.

Training and Development

Investing in training programs for employees ensures that they are up-to-date with the latest techniques and technologies. Continuous education fosters a culture of quality and precision. Training can include hands-on workshops, online courses, and certifications that enhance employees' skills and knowledge, ultimately benefiting the organization.

Collaboration and Communication

Encouraging collaboration between design, engineering, and fabrication teams enhances the overall quality of the final product. Open communication helps address potential issues early in the process. By fostering a collaborative environment, companies can leverage the diverse expertise of their teams to innovate and improve fabrication processes.

Conclusion

Ensuring quality and precision in sheet metal fabrication requires a comprehensive approach that encompasses design, material selection, fabrication techniques, quality control, and skilled labor. By focusing on these key areas, manufacturers can produce components that meet the highest standards of performance and reliability. As technology continues to evolve, staying informed about advancements in fabrication methods and materials will be essential for maintaining a competitive edge in the industry. Emphasizing quality and precision not only enhances product performance but also builds trust with customers, leading to long-term success in the market.

Frequently Asked Questions regarding Sheet Metal Fabrication

1. What are the most common materials used in sheet metal fabrication?

The most common materials include aluminum, stainless steel, mild steel, copper, and brass. Each material has unique properties that make it suitable for specific applications, such as aluminum's lightweight nature and stainless steel's corrosion resistance.

2. How does CAD software improve the sheet metal fabrication process?

CAD software enhances the fabrication process by allowing engineers to create detailed 3D models of components. This enables simulations to test fit and function before production, reducing errors and improving manufacturability through better design visualization.

3. What is the significance of tolerances in sheet metal fabrication?

Tolerances define the allowable variations in dimensions of fabricated parts. They are crucial for ensuring that components fit together correctly, function as intended, and meet performance standards. Clear tolerances help minimize defects and facilitate easier assembly.

4. What quality control measures are essential in sheet metal fabrication?

Essential quality control measures include regular inspections (visual, dimensional, and non-destructive testing), statistical process control (SPC) to monitor production consistency, and implementing corrective actions when deviations from standards are detected.

5. Why is skilled labor important in sheet metal fabrication?

Skilled labor is vital because experienced fabricators possess the knowledge and expertise to handle materials and processes effectively. They can troubleshoot issues, ensure high-quality workmanship, and adapt to challenges that arise during fabrication, ultimately leading to better product quality.