Selecting the right die casting manufacturer is crucial for ensuring the quality and efficiency of your production process. Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This method is widely used for producing complex shapes with high precision and excellent surface finish. However, the success of your project largely depends on choosing the right manufacturer. This article will guide you through the essential factors to consider when selecting a die casting manufacturer, ensuring that you make an informed decision.

Understanding Die Casting

What is Die Casting?

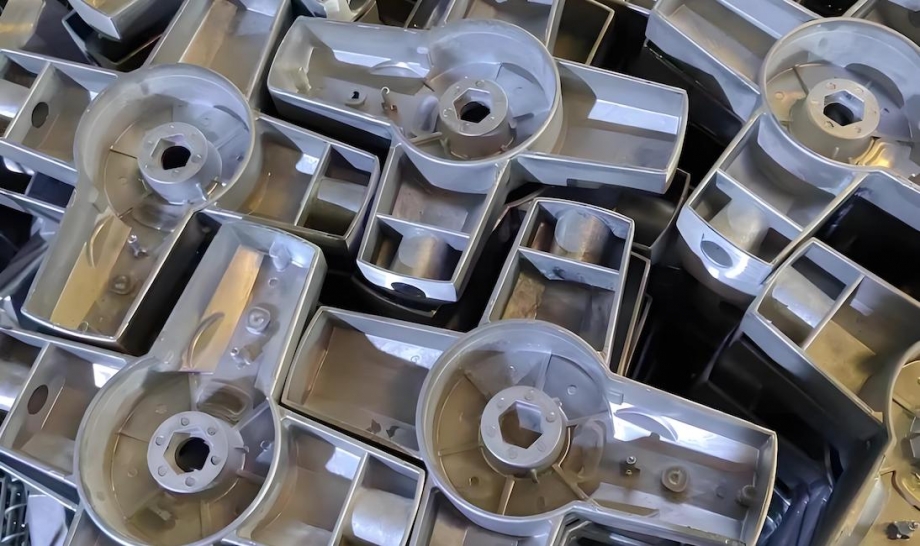

Die casting is a metal casting process characterized by the use of a mold, or die, into which molten metal is injected under high pressure. This process is suitable for producing parts with intricate designs and tight tolerances, making it a preferred choice in various industries, including automotive, aerospace, and consumer electronics. The die casting process allows for high-volume production, which can significantly reduce manufacturing costs per unit. Additionally, the ability to create complex geometries means that manufacturers can produce parts that would be difficult or impossible to achieve with other methods, such as machining or sand casting.

Types of Die Casting

There are two primary types of die casting: hot chamber and cold chamber. Hot chamber die casting is typically used for metals with low melting points, such as zinc and magnesium, while cold chamber die casting is used for higher melting point metals like aluminum and copper. Understanding the type of die casting that suits your project is essential when selecting a manufacturer. Each method has its advantages and limitations, influencing factors such as production speed, material choice, and the complexity of the parts being produced. For instance, hot chamber die casting allows for faster cycle times, while cold chamber die casting is better suited for producing larger and more robust components.

Key Factors to Consider When Choosing a Die Casting Manufacturer

Experience and Expertise

One of the first factors to consider is the manufacturer's experience in the die casting industry. A manufacturer with a proven track record will have the necessary expertise to handle various challenges that may arise during the production process. Look for manufacturers who have been in the industry for several years and have experience with projects similar to yours. Their familiarity with different materials, processes, and industry standards can be invaluable in ensuring that your project runs smoothly. Additionally, experienced manufacturers are more likely to have established relationships with suppliers, which can lead to better material quality and pricing.

Quality Assurance

Quality assurance is critical in die casting, as it directly impacts the performance and durability of the final product. Ensure that the manufacturer has a robust quality control system in place. This includes regular inspections, testing of materials, and adherence to industry standards. Certifications such as ISO 9001 can also indicate a commitment to quality. A strong quality assurance program not only helps in identifying defects early in the production process but also ensures that the final products meet the required specifications and performance standards. Manufacturers that invest in quality assurance are more likely to produce reliable and consistent parts, reducing the risk of costly rework or failures in the field.

Production Capabilities

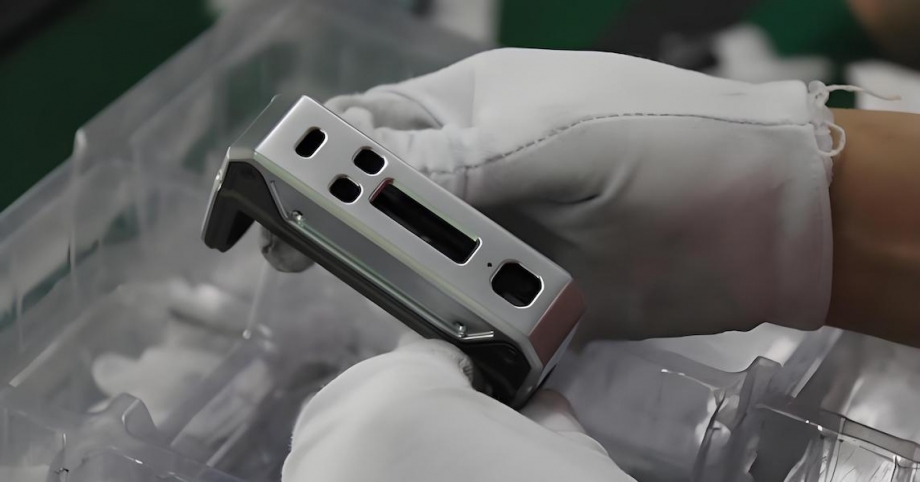

Evaluate the production capabilities of the manufacturer. This includes their ability to handle the volume of parts you require, the range of materials they can work with, and their technological capabilities. A manufacturer with advanced machinery and technology can produce parts more efficiently and with higher precision. Additionally, consider their ability to scale production up or down based on your needs. Flexibility in production capabilities can be a significant advantage, especially if your project requirements change over time or if you need to respond quickly to market demands.

Cost Considerations

While cost should not be the sole determining factor, it is essential to consider the overall cost of production. Request quotes from multiple manufacturers and compare them. Be cautious of prices that seem too good to be true, as they may indicate lower quality or hidden costs. Consider the total cost of ownership, which includes production costs, shipping, and any potential rework or defects. It is also wise to assess the long-term value of the relationship with the manufacturer. A slightly higher upfront cost may be justified if it results in better quality, fewer defects, and lower overall costs in the long run.

Lead Times

Lead time is another critical factor in the selection process. Understand the manufacturer's production schedule and their ability to meet your deadlines. A manufacturer with shorter lead times can help you bring your product to market faster, which can be a significant competitive advantage. Additionally, consider their ability to handle rush orders or unexpected changes in demand. A reliable manufacturer should be able to provide realistic timelines and communicate any potential delays promptly, allowing you to plan your production and inventory management effectively.

Communication and Support

Effective communication is vital for a successful partnership. Choose a manufacturer that is responsive and willing to provide support throughout the production process. This includes being available for consultations, providing updates on production status, and addressing any concerns that may arise. A manufacturer that prioritizes communication can help you navigate challenges more effectively and ensure that your project stays on track. Look for manufacturers that have dedicated account managers or customer service teams to facilitate smooth communication and support.

Location

The location of the manufacturer can impact shipping costs and lead times. Consider whether you prefer a local manufacturer for easier communication and logistics or if you are open to working with overseas manufacturers, which may offer cost advantages. Local manufacturers may provide faster turnaround times and easier access for site visits, while overseas manufacturers might offer lower production costs. Weigh the pros and cons of each option based on your specific needs, including the importance of face-to-face communication and the potential impact of shipping times on your project.

Customization and Flexibility

Your project may require specific customizations or adjustments during the production process. A good die casting manufacturer should be flexible and willing to accommodate changes as needed. This adaptability can be crucial in ensuring that the final product meets your specifications. Manufacturers that offer design assistance and prototyping services can also help you refine your product before full-scale production, reducing the risk of costly changes later in the process.

Environmental Considerations

In today's market, sustainability is becoming increasingly important. Consider manufacturers that prioritize environmentally friendly practices, such as recycling materials and reducing waste. This not only benefits the environment but can also enhance your brand's reputation. Many consumers and businesses are now looking for partners that align with their values, and choosing a manufacturer with sustainable practices can be a selling point for your products. Additionally, manufacturers that invest in energy-efficient processes and technologies may also offer cost savings in the long run.

References and Reviews

Before making a final decision, seek references from previous clients and read reviews about the manufacturer. This can provide valuable insights into their reliability, quality of work, and customer service. A manufacturer with positive feedback from clients is more likely to meet your expectations. Consider reaching out to past clients to ask about their experiences, including any challenges they faced and how the manufacturer addressed them. This firsthand information can be instrumental in making an informed choice.

Conclusion

Selecting the right die casting manufacturer is a critical step in ensuring the success of your project. By considering factors such as experience, quality assurance, production capabilities, cost, lead times, communication, location, customization, environmental practices, and client feedback, you can make an informed decision that aligns with your specific requirements. Taking the time to thoroughly evaluate potential manufacturers will ultimately lead to a more successful and efficient production process, resulting in high-quality products that meet your needs. A well-chosen manufacturing partner can not only enhance your production capabilities but also contribute to the overall success and growth of your business.

Frequently Asked Questions regarding Die Casting Manufacturer

1. What are the key benefits of using die casting for manufacturing?

Die casting offers several benefits, including high precision and repeatability, the ability to produce complex shapes, excellent surface finish, and reduced material waste. It is also suitable for high-volume production, which can lower the cost per unit.

2. How can I assess the quality of a die casting manufacturer?

To assess the quality of a die casting manufacturer, check for certifications such as ISO 9001, review their quality control processes, and request samples of their previous work. Additionally, seek references from past clients to gauge their satisfaction with the manufacturer's quality.

3. What materials are commonly used in die casting?

Common materials used in die casting include aluminum, zinc, magnesium, and copper. Each material has its unique properties, making it suitable for different applications. For instance, aluminum is often used for lightweight components, while zinc is favored for its excellent corrosion resistance.

4. How important is communication during the manufacturing process?

Communication is crucial during the manufacturing process as it ensures that both parties are aligned on project specifications, timelines, and any potential issues. A manufacturer that prioritizes clear and open communication can help prevent misunderstandings and facilitate smoother project execution.

5. What should I do if I need to make changes to my design after production has started?

If you need to make changes to your design after production has started, communicate with your manufacturer as soon as possible. A good manufacturer should be flexible and willing to accommodate changes, but it's essential to understand how these changes may impact production timelines and costs.