In the fast-paced world of electronics manufacturing, efficiency is paramount. Surface Mount Technology (SMT) feeders play a crucial role in enhancing production efficiency by ensuring that components are delivered accurately and quickly to the assembly line. This article explores how selecting the right SMT feeder can significantly improve your production efficiency, focusing on various aspects such as speed, accuracy, flexibility, and maintenance.

Understanding SMT Feeders

SMT feeders are devices used in the assembly of electronic components onto printed circuit boards (PCBs). They are responsible for delivering components from their packaging to the pick-and-place machine, which then places them onto the PCB. The right SMT feeder can streamline this process, reducing downtime and increasing throughput.

SMT feeders come in various designs and configurations, each tailored to meet specific production needs. Understanding the different types of feeders available and their functionalities is essential for manufacturers looking to optimize their production lines. By selecting the appropriate feeder, companies can ensure that their assembly processes are not only efficient but also capable of adapting to changing production demands.

Types of SMT Feeders

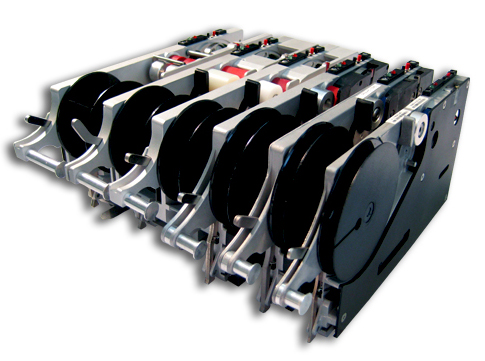

1. Tape Feeders: These are the most common type, designed to handle components that come in tape and reel packaging. They ensure consistent and precise feeding of small components, which is critical for high-density PCBs. Tape feeders are often equipped with advanced features such as automatic calibration and error detection, which help maintain accuracy and reduce the risk of component misplacement.

2. Stick Feeders: Used for components supplied in stick packaging, these feeders are ideal for larger and irregularly shaped parts. Stick feeders can accommodate a variety of component sizes, making them versatile for different production runs. Their design allows for easy loading and unloading, which can significantly reduce setup times between production batches.

3. Bulk Feeders: These feeders handle components in bulk, allowing for high-speed feeding of larger quantities. Bulk feeders are particularly useful in high-volume production environments where speed is essential. They can be integrated with automated systems to further enhance efficiency, minimizing the need for manual intervention.

4. Custom Feeders: Tailored to specific production needs, these feeders can accommodate unique component shapes and sizes. Custom feeders are designed based on the specific requirements of a production line, ensuring that they can handle the unique challenges posed by certain components. This customization can lead to significant improvements in both speed and accuracy.

The Impact of the Right SMT Feeder on Production Efficiency

1. Increased Speed

One of the primary benefits of using the right SMT feeder is the increase in speed. High-quality feeders are engineered for rapid component delivery, allowing pick-and-place machines to maintain optimal throughput. This increased speed leads to shorter cycle times and higher production rates, which are essential for meeting tight deadlines in the electronics industry.

Moreover, faster feeders can significantly reduce the time required for changeovers between different production runs. This capability is particularly beneficial in environments where manufacturers need to switch frequently between different products or configurations. By minimizing the time spent on changeovers, companies can maximize their production output and improve overall efficiency.

2. Enhanced Accuracy

Accuracy is crucial in SMT assembly. The right feeder ensures that components are placed precisely where they need to go, reducing defects and rework time. High-quality feeders minimize misalignment and component jams, which can lead to costly downtime. By investing in feeders that offer superior accuracy, manufacturers can significantly enhance the quality of their products.

In addition to improving placement accuracy, advanced feeders often come equipped with features that allow for real-time monitoring and adjustments. This capability enables operators to quickly identify and rectify any issues that may arise during the assembly process, further enhancing the overall accuracy and reliability of the production line.

3. Flexibility in Production

The ability to handle a variety of components is another advantage of selecting the right SMT feeder. Many modern feeders are designed to accommodate different component sizes and types, allowing manufacturers to switch between production runs with minimal setup time. This flexibility is vital in today's market, where product lifecycles are short, and the demand for customization is high.

Flexible feeders can also support the production of mixed technology boards, where different types of components are used on the same PCB. This capability allows manufacturers to respond quickly to changing market demands and customer preferences, ensuring that they remain competitive in a rapidly evolving industry.

4. Reduced Downtime

Downtime can be a significant cost in any manufacturing process. The right SMT feeder can help reduce downtime through features such as quick-change capabilities and reliable component delivery. Regular maintenance and proper setup of feeders can also prevent breakdowns, ensuring that production lines run smoothly.

Additionally, implementing predictive maintenance strategies can further minimize downtime. By using data analytics and monitoring systems, manufacturers can anticipate potential issues before they lead to equipment failure. This proactive approach allows for timely interventions, keeping production lines operational and efficient.

5. Improved Component Handling

Effective component handling is essential for maintaining production efficiency. The right SMT feeder minimizes the risk of damage to components during the feeding process. This is particularly important for sensitive electronic parts that can be easily damaged. By ensuring that components are handled gently and accurately, manufacturers can reduce waste and improve overall production efficiency.

Furthermore, advanced feeders often incorporate features such as vibration control and gentle handling mechanisms, which help protect delicate components during transport. This attention to detail not only enhances the quality of the final product but also contributes to a more sustainable manufacturing process by reducing material waste.

Choosing the Right SMT Feeder

When selecting an SMT feeder, several factors should be considered to ensure optimal performance:

Compatibility with Existing Equipment

Ensure that the feeder you choose is compatible with your current pick-and-place machines and other equipment on your line. This compatibility is crucial for seamless integration and optimal performance. Manufacturers should also consider the ease of integration with existing software systems, as this can impact overall efficiency.

Type of Components

Consider the types of components you will be using most frequently. Choose a feeder that can handle these efficiently. For instance, if your production line primarily uses small components, a tape feeder may be the best choice. Understanding the specific requirements of your components will help you select a feeder that maximizes efficiency and minimizes handling issues.

Speed Requirements

Evaluate the speed requirements of your production line. High-speed feeders are essential for high-volume production environments, while slower feeders may suffice for lower-volume operations. It's important to balance speed with accuracy to ensure that production goals are met without compromising quality.

Maintenance and Support

Select feeders from reputable SMT feeder manufacturers that offer reliable support and maintenance services. Regular maintenance is essential for ensuring the longevity and performance of your feeders. Manufacturers should also consider the availability of spare parts and technical support when choosing a supplier.

Best Practices for Maximizing SMT Feeder Efficiency

To get the most out of your SMT feeders, consider implementing the following best practices:

Regular Maintenance

Regular maintenance and inspection of feeders are crucial for preventing breakdowns and ensuring smooth operations. Cleaning, lubricating, and replacing worn-out components can significantly enhance feeder performance. Establishing a routine maintenance schedule can help identify potential issues before they escalate, ensuring that production remains uninterrupted.

Optimize Machine Setup

Optimizing the machine setup can lead to improved efficiency. This includes selecting the right component feeders, optimizing placement parameters, and grouping similar components together to reduce changeover times. By carefully planning the layout of the production line and the sequence of operations, manufacturers can streamline their processes and enhance overall productivity.

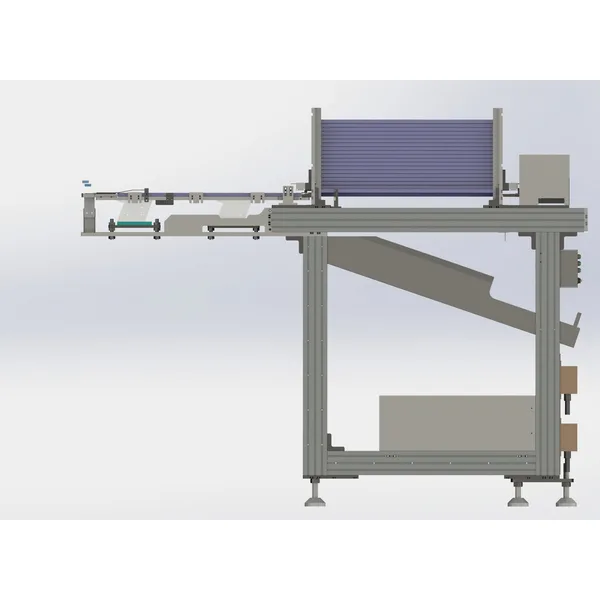

Automate Material Handling

Automating the material handling process can also increase SMT mounter efficiency. Implementing a material management system and using automatic guided vehicles (AGVs) to transport materials can reduce manual intervention and improve overall production efficiency. Automation not only speeds up the handling process but also minimizes the risk of human error, leading to more consistent results.

Training and Skill Development

Investing in training for your operators can lead to better handling of SMT feeders and improved overall efficiency. Skilled operators are more likely to identify and resolve issues quickly, minimizing downtime. Providing ongoing training and development opportunities can help ensure that your team is equipped with the latest knowledge and skills needed to operate and maintain SMT feeders effectively.

Conclusion

In conclusion, the right SMT feeder is a critical component in enhancing production efficiency in electronics manufacturing. By increasing speed, improving accuracy, reducing downtime, and ensuring better component handling, high-quality feeders contribute significantly to overall productivity and cost-effectiveness. As technology continues to advance, investing in top-tier feeding solutions will be vital for staying competitive in this fast-paced industry.

Frequently Asked Questions

1. What is the primary function of an SMT feeder?

- The primary function of an SMT feeder is to deliver electronic components from their packaging to the pick-and-place machine for assembly onto PCBs.

2. How does the type of feeder affect production efficiency?

- Different types of feeders are designed for specific component sizes and packaging. Choosing the right type can enhance speed, accuracy, and flexibility in production.

3. What maintenance practices should be followed for SMT feeders?

- Regular cleaning, lubrication, and inspection for wear and tear are essential maintenance practices to ensure optimal performance of SMT feeders.

4. Can SMT feeders handle different types of components?

- Yes, many modern SMT feeders are designed to accommodate a variety of component sizes and types, providing flexibility in production.

5. What are the benefits of automating material handling in SMT production?

- Automating material handling reduces manual intervention, increases material uptime, and improves overall production efficiency by streamlining the supply chain.