Sheet metal fabrication is a crucial aspect of modern manufacturing, offering a range of benefits that can significantly enhance production efficiency, reduce costs, and improve product quality. This article explores the various ways in which sheet metal fabrication can transform your manufacturing processes, detailing its advantages, techniques, and applications.

Understanding Sheet Metal Fabrication

What is Sheet Metal Fabrication?

Sheet metal fabrication involves the process of transforming flat sheets of metal into various shapes and structures through cutting, bending, and assembling. This process is essential in creating components for a wide array of industries, including automotive, aerospace, electronics, and construction. The versatility of sheet metal allows manufacturers to produce everything from simple brackets to complex assemblies, making it a foundational element in many manufacturing operations. The ability to manipulate metal sheets into desired forms enables the creation of lightweight yet durable products, which is increasingly important in today's market.

Key Processes in Sheet Metal Fabrication

The primary processes involved in sheet metal fabrication include:

◆ Cutting: This can be achieved through various methods such as laser cutting, waterjet cutting, and shearing. Each method offers different advantages in terms of precision and material compatibility. For instance, laser cutting is known for its ability to create intricate designs with minimal material waste, while waterjet cutting is ideal for thicker materials that require a non-thermal cutting method to avoid altering the material properties.

◆ Bending: This process shapes the metal sheets into desired angles and forms, often using press brakes or other bending machines. Bending is critical for creating components that need to fit together precisely, and advancements in technology have led to the development of automated bending machines that enhance accuracy and reduce production time.

◆ Welding: Joining different metal parts together is crucial for creating complex assemblies. Techniques such as MIG, TIG, and spot welding are commonly used. Each welding method has its own set of advantages, with MIG welding being favored for its speed and efficiency, while TIG welding is preferred for its precision and ability to weld thinner materials.

◆ Finishing: This includes processes like painting, coating, or polishing to enhance the appearance and durability of the final product. Finishing not only improves aesthetics but also provides protective layers that can prevent corrosion and wear, extending the lifespan of the components.

Benefits of Sheet Metal Fabrication

Enhanced Precision and Accuracy

One of the most significant advantages of sheet metal fabrication is the high level of precision it offers. Advanced technologies such as CNC (Computer Numerical Control) machines and CAD (Computer-Aided Design) software ensure that components are manufactured to exact specifications. This precision reduces the likelihood of errors and rework, leading to higher quality products. The ability to produce parts with tight tolerances is particularly important in industries such as aerospace and medical devices, where even minor deviations can have serious consequences.

Cost Efficiency

Sheet metal fabrication can lead to substantial cost savings in manufacturing. By optimizing the design and production processes, manufacturers can minimize material waste and reduce labor costs. Techniques such as Design for Manufacturing (DFM) help streamline production, making it more cost-effective. Additionally, the use of automated processes can significantly lower labor costs, as machines can operate continuously with minimal human intervention, allowing companies to allocate resources more effectively.

Versatility in Design

Sheet metal fabrication allows for a high degree of customization. Manufacturers can create a wide variety of shapes and sizes, accommodating specific customer needs. This versatility is particularly beneficial in industries that require bespoke components or rapid prototyping. The ability to quickly adapt designs based on customer feedback or market trends enables manufacturers to stay competitive and responsive to changing demands.

Improved Production Speed

With the implementation of automated processes and advanced machinery, sheet metal fabrication can significantly speed up production times. Automation reduces manual labor and increases throughput, allowing manufacturers to meet tight deadlines and respond quickly to market demands. The integration of robotics in the fabrication process can further enhance efficiency, as robots can perform repetitive tasks with high precision and speed, freeing up human workers for more complex operations.

Sustainability and Environmental Impact

Modern sheet metal fabrication techniques are increasingly focused on sustainability. Many processes are designed to minimize waste and energy consumption. Additionally, metals are recyclable, which contributes to a more sustainable manufacturing cycle. By adopting eco-friendly practices, manufacturers can not only reduce their environmental footprint but also appeal to a growing market of environmentally conscious consumers.

Techniques in Sheet Metal Fabrication

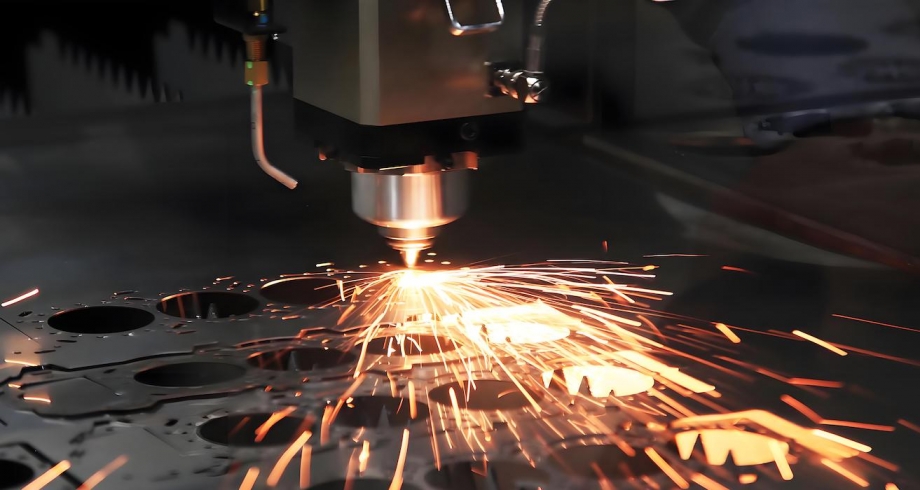

Laser Cutting

Laser cutting is one of the most precise methods for cutting sheet metal. It uses a high-powered laser to melt or vaporize the material, allowing for intricate designs and tight tolerances. This technique is ideal for complex shapes and is widely used in various industries. The ability to cut with such precision means that manufacturers can create parts that fit together perfectly, reducing the need for additional machining or adjustments.

Waterjet Cutting

Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through metal. This method is particularly effective for thicker materials and does not produce heat-affected zones, preserving the integrity of the metal. Waterjet cutting is also versatile, as it can be used on a variety of materials, including metals, plastics, and composites, making it a valuable tool in a manufacturer's arsenal.

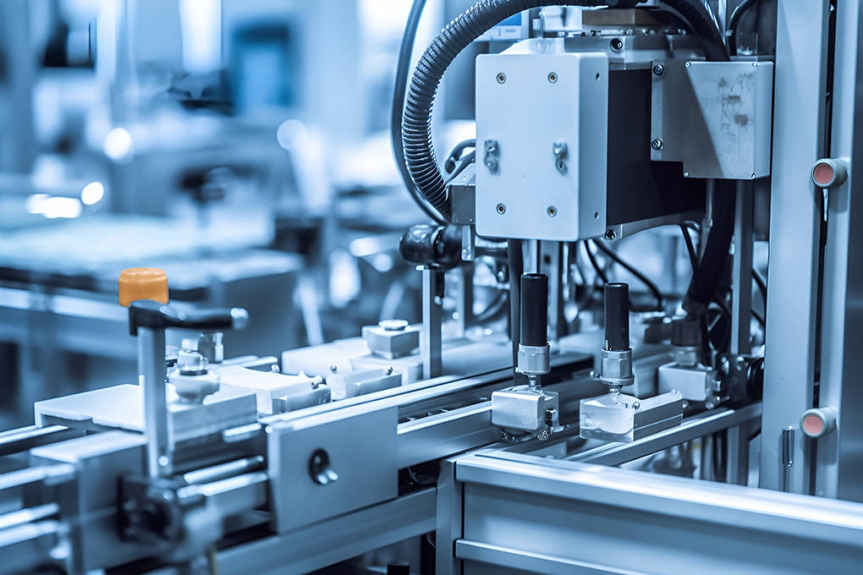

CNC Machining

CNC machining involves the use of computer-controlled machines to perform various fabrication tasks. This technology enhances precision and allows for the automation of complex processes, reducing the risk of human error. CNC machines can execute intricate designs with high repeatability, making them ideal for mass production where consistency is key.

Press Brake Bending

Press brakes are used to bend sheet metal into specific angles. This process is essential for creating parts that require precise bends and folds, ensuring that components fit together correctly in the final assembly. The evolution of press brake technology, including the introduction of servo-electric drives, has improved energy efficiency and reduced cycle times, further enhancing productivity.

Applications of Sheet Metal Fabrication

Automotive Industry

In the automotive sector, sheet metal fabrication is used to produce a wide range of components, including body panels, frames, and brackets. The ability to create lightweight yet strong parts is crucial for improving fuel efficiency and performance. As the automotive industry shifts towards electric vehicles, the demand for innovative sheet metal solutions that support lightweight designs and battery housing is increasing.

Aerospace Industry

The aerospace industry relies heavily on sheet metal fabrication for manufacturing aircraft components. The need for high precision and lightweight materials makes this process essential for ensuring safety and performance in aviation. Components such as fuselage skins, wing structures, and engine housings are often fabricated from high-strength alloys, showcasing the importance of advanced fabrication techniques in this sector.

Electronics Manufacturing

Sheet metal fabrication is also vital in the electronics industry, where it is used to create enclosures, heat sinks, and other components. The ability to produce intricate designs and ensure proper thermal management is critical in this field. As electronic devices become smaller and more powerful, the demand for efficient heat dissipation solutions has led to innovative sheet metal designs that enhance performance and reliability.

Construction and Architecture

In construction, sheet metal fabrication is used for roofing, siding, and structural components. The durability and versatility of metal make it an ideal choice for various architectural applications. Additionally, the aesthetic appeal of metal finishes has made it a popular choice in modern architecture, allowing for creative designs that blend functionality with visual impact.

Challenges in Sheet Metal Fabrication

Material Limitations

While sheet metal fabrication offers many advantages, it is not without its challenges. Certain materials may pose difficulties during fabrication, such as cracking or warping. Understanding the properties of different metals is essential for successful fabrication. Manufacturers must carefully select materials based on their specific applications and the fabrication processes involved to avoid issues that could compromise the integrity of the final product.

Complexity of Designs

As designs become more intricate, the fabrication process can become more complicated. Advanced machinery and skilled labor are required to handle complex shapes, which can increase production costs and time. Manufacturers must balance the desire for innovative designs with the practicalities of production capabilities, often requiring collaboration between design and engineering teams to ensure feasibility.

Initial Setup Costs

Setting up a sheet metal fabrication facility can require significant investment in machinery and tooling. However, the long-term benefits often outweigh these initial costs, especially when considering the efficiency gains and cost savings. Manufacturers must conduct thorough cost-benefit analyses to determine the best approach for their operations, weighing the potential return on investment against the upfront expenditures.

Conclusion

Sheet metal fabrication is a transformative process that can significantly improve manufacturing efficiency, reduce costs, and enhance product quality. By leveraging advanced technologies and techniques, manufacturers can create precise, customized components that meet the demands of various industries. As the manufacturing landscape continues to evolve, the role of sheet metal fabrication will only become more critical in driving innovation and sustainability. Embracing these practices can lead to a more efficient, cost-effective, and environmentally friendly manufacturing process, positioning companies for success in an increasingly competitive market.

Frequently Asked Questions regarding Sheet Metal Fabrication

1. What materials are commonly used in sheet metal fabrication?

Common materials used in sheet metal fabrication include steel, aluminum, copper, brass, and stainless steel. Each material has unique properties that make it suitable for different applications, such as strength, weight, corrosion resistance, and conductivity.

2. How does automation impact sheet metal fabrication?

Automation significantly enhances sheet metal fabrication by increasing production speed, improving precision, and reducing labor costs. Automated machines, such as CNC routers and robotic welders, can operate continuously and perform complex tasks with high accuracy, leading to more efficient manufacturing processes.

3. What industries benefit the most from sheet metal fabrication?

Industries that benefit greatly from sheet metal fabrication include automotive, aerospace, electronics, construction, and HVAC (heating, ventilation, and air conditioning). Each of these sectors relies on custom metal components for various applications, from structural parts to intricate electronic enclosures.

4. What are the environmental benefits of sheet metal fabrication?

Sheet metal fabrication offers several environmental benefits, including reduced material waste through precise cutting techniques, the recyclability of metals, and energy-efficient manufacturing processes. By minimizing waste and utilizing sustainable practices, manufacturers can lower their environmental impact.

5. How can manufacturers ensure quality in sheet metal fabrication?

Manufacturers can ensure quality in sheet metal fabrication by implementing strict quality control measures, using advanced technologies like CNC machining for precision, and conducting regular inspections throughout the fabrication process. Additionally, investing in skilled labor and training can help maintain high standards in production.