CNC (Computer Numerical Control) milling has revolutionized the manufacturing industry by providing precision, efficiency, and flexibility in machining processes. As technology advances, so do the techniques used in CNC milling, leading to significant improvements in efficiency. This article explores various advanced CNC milling techniques and their impact on manufacturing efficiency.

Understanding CNC Milling

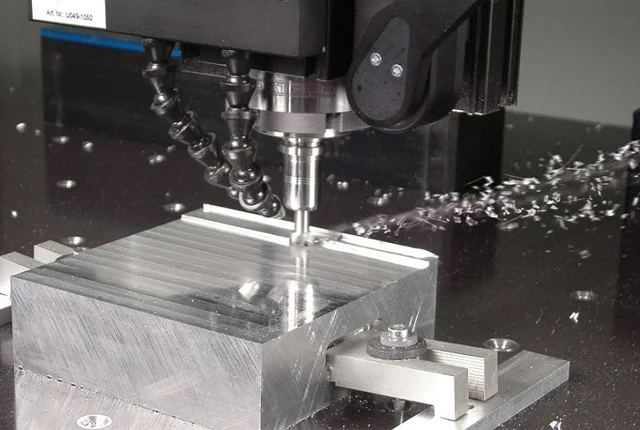

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece. This process allows for the creation of complex shapes and designs with high precision. The efficiency of CNC milling is influenced by several factors, including machine capabilities, tooling, and programming techniques. Understanding these elements is crucial for manufacturers looking to optimize their production processes and reduce costs.

The Basics of CNC Milling

CNC milling machines operate by moving a cutting tool along multiple axes to shape the material. The most common types of CNC milling machines include vertical and horizontal mills, each offering unique advantages depending on the application. Vertical mills are often used for smaller, intricate parts, while horizontal mills are better suited for larger workpieces. The integration of advanced technologies in these machines has led to enhanced capabilities and improved efficiency, allowing manufacturers to tackle a wider range of projects with greater ease.

Advanced CNC Milling Techniques

High-Speed Machining

High-speed machining (HSM) is a technique that involves operating CNC milling machines at higher speeds than traditional methods. This approach reduces cycle times and increases productivity. HSM utilizes specialized cutting tools and optimized tool paths to achieve faster material removal rates while maintaining precision. The ability to operate at high speeds not only enhances productivity but also allows for more complex geometries to be machined in a shorter time frame.

Benefits of High-Speed Machining

Reduced Cycle Times: By increasing the speed of the machining process, manufacturers can produce parts more quickly, leading to shorter lead times. This is particularly beneficial in industries where time-to-market is critical.

Improved Surface Finish: HSM often results in better surface finishes due to the reduced cutting forces and vibrations during machining. A smoother finish can reduce the need for secondary operations, further enhancing efficiency.

Extended Tool Life: The use of advanced tooling materials and coatings in HSM can lead to longer tool life, reducing the frequency of tool changes. This not only saves costs but also minimizes downtime associated with tool replacement.

Adaptive Machining

Adaptive machining is a technique that allows CNC machines to adjust their parameters in real-time based on feedback from the machining process. This approach enhances efficiency by optimizing cutting conditions dynamically. By continuously monitoring the machining environment, adaptive machining can respond to variations in material properties or tool wear, ensuring that the process remains efficient throughout.

Key Features of Adaptive Machining

Real-Time Monitoring: Sensors and software monitor the machining process, allowing for adjustments to be made on-the-fly. This capability is crucial for maintaining optimal performance, especially in high-volume production settings.

Optimized Cutting Conditions: By adapting to changes in material properties or tool wear, adaptive machining ensures optimal cutting conditions are maintained throughout the process. This leads to improved quality and reduced scrap rates.

Reduced Waste: This technique minimizes material waste by ensuring that the machining process is as efficient as possible. By optimizing every aspect of the machining process, manufacturers can significantly reduce their environmental impact.

Toolpath Optimization

Toolpath optimization involves the strategic planning of the cutting tool's movement to minimize machining time and maximize efficiency. Advanced software algorithms analyze the machining process to create the most efficient tool paths. This not only speeds up production but also enhances the overall quality of the finished product.

Advantages of Toolpath Optimization

Minimized Tool Changes: Efficient tool paths reduce the need for frequent tool changes, leading to less downtime. This is particularly important in high-volume production environments where every minute counts.

Lower Energy Consumption: Optimized paths can lead to reduced energy consumption during machining, contributing to overall cost savings. This is increasingly important as manufacturers seek to reduce their carbon footprint.

Enhanced Precision: By minimizing unnecessary movements, toolpath optimization can improve the precision of the final product. This is essential in industries where tolerances are tight and quality is paramount.

The Role of Advanced Materials

The choice of materials used in CNC milling can significantly impact efficiency. Advanced materials, such as composites and high-strength alloys, can enhance the performance of CNC milling processes. These materials often require specialized machining techniques, which can further improve efficiency and product quality.

Benefits of Using Advanced Materials

Increased Durability: Advanced materials often exhibit superior wear resistance, leading to longer tool life and reduced maintenance costs. This is particularly beneficial in industries that require high-performance components.

Improved Machinability: Some advanced materials are designed specifically for machining, allowing for faster processing and better surface finishes. This can lead to significant time savings in production.

Weight Reduction: Lightweight materials can lead to reduced energy consumption during machining and transportation. This is especially important in industries such as aerospace, where weight savings can translate to significant performance improvements.

Automation and Robotics in CNC Milling

The integration of automation and robotics in CNC milling processes has transformed the industry by enhancing efficiency and reducing labor costs. Automated systems can operate continuously, allowing for higher production rates and improved consistency in product quality.

Advantages of Automation

Increased Production Rates: Automated CNC milling systems can operate continuously, leading to higher production rates. This is particularly advantageous in industries with high demand for precision components.

Consistency and Quality: Automation ensures consistent machining quality, reducing the likelihood of human error. This is crucial in maintaining customer satisfaction and meeting regulatory standards.

Flexibility: Automated systems can be programmed to handle various tasks, allowing manufacturers to adapt quickly to changing demands. This flexibility is essential in today’s fast-paced manufacturing environment.

The Impact of Software and Programming

Advanced software solutions play a crucial role in improving the efficiency of CNC milling processes. These programs assist in everything from design to production planning, enabling manufacturers to streamline their operations and reduce costs.

Key Software Features

Simulation and Visualization: Advanced software allows manufacturers to simulate the machining process, identifying potential issues before production begins. This proactive approach can save time and resources by preventing costly mistakes.

Data Analytics: Software can analyze production data to identify inefficiencies and suggest improvements. By leveraging data analytics, manufacturers can make informed decisions that enhance productivity.

Integration with CAD/CAM: Seamless integration with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software streamlines the design-to-production workflow. This integration reduces the time required to bring new products to market.

Conclusion

Advanced CNC milling techniques are essential for improving efficiency in manufacturing processes. By leveraging high-speed machining, adaptive machining, toolpath optimization, advanced materials, automation, and sophisticated software, manufacturers can achieve significant gains in productivity and quality. As technology continues to evolve, the potential for further improvements in CNC milling efficiency remains vast, promising a future of even greater capabilities in the manufacturing sector.

Frequently Asked Questions regarding CNC Milling service

1. What is CNC milling, and how does it differ from traditional milling?

Answer: CNC milling is a computer-controlled machining process that uses programmed commands to control the movement of cutting tools. Unlike traditional milling, which relies on manual operation, CNC milling offers higher precision, repeatability, and the ability to produce complex shapes with minimal human intervention.

2. How does high-speed machining (HSM) improve efficiency in CNC milling?

Answer: High-speed machining improves efficiency by allowing CNC machines to operate at significantly higher speeds, reducing cycle times and increasing material removal rates. This leads to faster production, improved surface finishes, and extended tool life, ultimately resulting in lower manufacturing costs.

3. What are the benefits of using adaptive machining in CNC processes?

Answer: Adaptive machining provides real-time adjustments to machining parameters based on feedback from the process. This leads to optimized cutting conditions, reduced waste, improved quality, and the ability to respond quickly to variations in material properties or tool wear, enhancing overall efficiency.

4. How does toolpath optimization contribute to CNC milling efficiency?

Answer: Toolpath optimization minimizes unnecessary movements of the cutting tool, reducing machining time and energy consumption. By strategically planning the tool's movement, manufacturers can decrease cycle times, lower operational costs, and improve the precision of the final product.

5. What role does automation play in enhancing CNC milling efficiency?

Answer: Automation in CNC milling allows machines to operate continuously with minimal human intervention, increasing production rates and ensuring consistent quality. Automated systems can quickly adapt to different tasks, reducing downtime and labor costs while improving overall operational efficiency.