The world of lighting technology is rapidly evolving, and at the forefront of this transformation is the development of custom LED lenses. These lenses are crucial for optimizing the performance and efficiency of LED lighting systems. This article will explore the complete journey of custom LED lens development, focusing on the role of Original Equipment Manufacturer (OEM) experts in this process.

Understanding LED Lenses

LED lenses are optical components designed to control the distribution of light emitted from LED sources. They play a vital role in enhancing the efficiency and effectiveness of lighting solutions. The design and manufacturing of these lenses involve a complex interplay of materials, shapes, and optical properties. Unlike traditional lighting solutions, LED technology allows for greater flexibility in design, enabling the creation of lenses that can manipulate light in innovative ways. This capability is essential for applications ranging from residential lighting to industrial and automotive uses, where precise light control can significantly impact performance and user experience.

Importance of Customization

Customization is essential in the LED lens industry due to the diverse applications of LED lighting. Different environments and uses require specific lens designs to achieve optimal lighting performance. For instance, lenses used in automotive lighting differ significantly from those used in architectural lighting. The ability to tailor lenses to specific needs not only enhances functionality but also improves aesthetic appeal. This need for tailored solutions has led to the rise of OEM factories specializing in custom LED lens production. By collaborating closely with clients, these factories can develop lenses that not only meet technical specifications but also align with brand identity and design preferences.

The Role of OEM Experts

OEM experts are pivotal in the development of custom LED lenses. They bring together advanced technology, design expertise, and manufacturing capabilities to create lenses that meet specific customer requirements. The collaboration between lighting brands and OEM factories ensures that the final product aligns with market demands and technological advancements. OEM experts often have access to cutting-edge technologies and materials, allowing them to innovate continuously. Their experience in the industry enables them to anticipate challenges and provide solutions that enhance the overall quality and performance of the lenses.

Key Stages in the Development Process

The journey from concept to production of custom LED lenses involves several critical stages:

1. Conceptualization: This initial phase involves brainstorming and defining the specific requirements for the LED lens. Factors such as light distribution, material selection, and application context are considered. During this stage, stakeholders from various departments, including marketing, engineering, and design, collaborate to ensure that all perspectives are taken into account. This multidisciplinary approach helps in identifying unique challenges and opportunities early in the process.

2. Design: Once the concept is established, the design phase begins. This includes creating detailed specifications and prototypes. Advanced software tools are often used to simulate the optical performance of the lens. Designers utilize computer-aided design (CAD) software to create intricate models that can be tested virtually. This not only speeds up the design process but also allows for adjustments to be made before any physical prototypes are produced, saving time and resources.

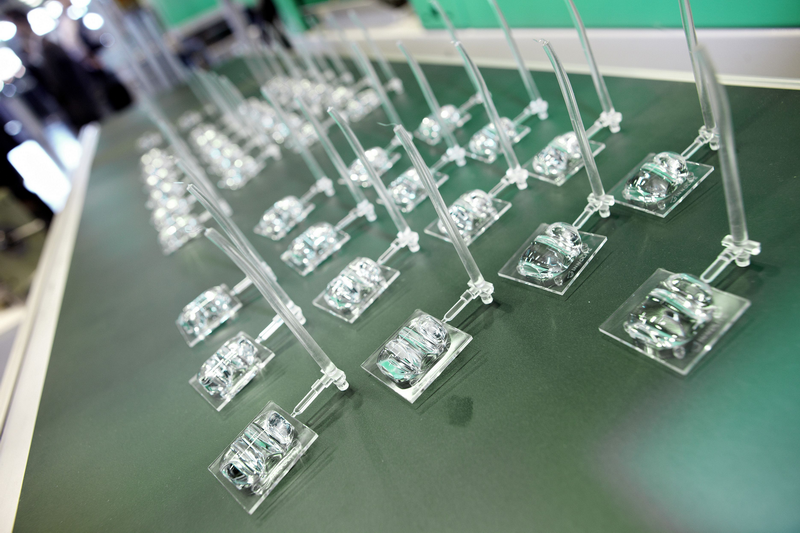

3. Prototyping: Prototypes are created to test the design's feasibility. This stage is crucial for identifying any potential issues before mass production. OEM experts utilize rapid prototyping techniques to expedite this process. Techniques such as 3D printing allow for quick iterations of design changes, enabling teams to evaluate multiple configurations in a short time. Feedback from these prototypes is invaluable, as it provides insights into the practical performance of the lens in real-world conditions.

4. Testing and Validation: Prototypes undergo rigorous testing to ensure they meet performance standards. This includes evaluating light output, efficiency, and durability. Feedback from these tests is used to refine the design further. Testing may involve both laboratory conditions and field tests to assess how the lenses perform in various environments. This comprehensive validation process ensures that the final product not only meets but exceeds industry standards.

5. Production: After successful validation, the lens moves into full-scale production. OEM factories employ advanced manufacturing techniques, such as injection molding and CNC machining, to produce high-quality lenses efficiently. The choice of manufacturing method depends on the complexity of the lens design and the volume of production required. OEM factories are equipped with state-of-the-art machinery that allows for precision and consistency in every batch produced.

6. Quality Control: Throughout the production process, quality control measures are implemented to ensure that each lens meets the required specifications. This includes visual inspections and performance testing. Quality assurance teams work closely with production staff to monitor processes and identify any deviations from standards. This proactive approach helps in maintaining high-quality output and minimizing defects.

7. Delivery and Support: Once the lenses are produced, they are delivered to clients. OEM experts often provide ongoing support, helping clients integrate the lenses into their lighting solutions effectively. This support can include technical assistance, installation guidance, and troubleshooting. Building strong relationships with clients is essential for OEMs, as it fosters trust and encourages repeat business.

Challenges in Custom LED Lens Development

While the journey from concept to production is exciting, it is not without challenges. Some common issues faced during the development of custom LED lenses include:

- Material Selection: Choosing the right materials is critical for achieving the desired optical properties and durability. OEM experts must stay updated on the latest materials and technologies. The selection process often involves balancing performance characteristics, such as light transmission and thermal resistance, with cost considerations.

- Design Complexity: As lighting applications become more sophisticated, the designs of LED lenses also become more complex. Balancing performance with manufacturability is a constant challenge. Designers must consider how intricate features can be produced without compromising quality or increasing costs excessively.

- Cost Management: Customization often leads to higher production costs. OEM factories must find ways to manage these costs while maintaining quality. This may involve optimizing production processes, sourcing materials more efficiently, or leveraging economies of scale.

- Market Trends: The lighting industry is influenced by rapidly changing trends and technologies. OEM experts must be agile and responsive to these changes to remain competitive. Keeping abreast of emerging technologies, such as smart lighting and energy-efficient solutions, is essential for staying relevant in the market.

Future Trends in LED Lens Development

The future of custom LED lens development is promising, with several trends shaping the industry:

- Sustainability: There is a growing emphasis on sustainable materials and manufacturing processes. OEM factories are exploring eco-friendly options to reduce their environmental impact. This includes using recyclable materials and implementing energy-efficient production methods.

- Smart Lighting: The integration of smart technology into lighting solutions is on the rise. Custom LED lenses will need to accommodate features such as sensors and connectivity. This trend is driving innovation in lens design, as manufacturers seek to create products that enhance the functionality of smart lighting systems.

- Advanced Optics: Innovations in optical design, such as freeform optics, are expanding the possibilities for custom LED lenses. These advancements allow for more precise control of light distribution, enabling the creation of lenses that can adapt to various lighting scenarios.

- Increased Collaboration: As the demand for customized solutions grows, collaboration between lighting brands and OEM experts will become even more critical. This partnership will drive innovation and ensure that products meet market needs. Collaborative efforts can lead to the development of groundbreaking technologies and designs that set new industry standards.

Conclusion

The journey of custom LED lens development is a complex yet rewarding process that involves collaboration between lighting brands and OEM experts. From conceptualization to production, each stage is crucial in creating high-quality, efficient lighting solutions. As the industry continues to evolve, the role of OEM factories will be vital in meeting the growing demand for customized LED lenses. By embracing innovation and sustainability, OEM experts can lead the way in shaping the future of lighting technology.

Frequently Asked Questions

1. What are custom LED lenses?

Custom LED lenses are optical components designed to control the light emitted from LED sources, tailored to specific applications and performance requirements.

2. Why is customization important in LED lens development?

Customization allows for the optimization of light distribution and performance based on the unique needs of different environments and applications.

3. What role do OEM experts play in the development process?

OEM experts provide the necessary technology, design expertise, and manufacturing capabilities to create custom LED lenses that meet specific customer requirements.

4. What are the key stages in the development of custom LED lenses?

The key stages include conceptualization, design, prototyping, testing and validation, production, quality control, and delivery.

5. What are some challenges faced in custom LED lens development?

Challenges include material selection, design complexity, cost management, and keeping up with market trends.