The development of custom LED lenses is a fascinating journey that transforms innovative ideas into tangible products. This process involves several stages, from initial concept design to final production, ensuring that the lenses meet specific lighting requirements and applications. In this article, we will explore the intricate steps involved in custom LED lens development, the technologies used, and the importance of collaboration between designers and manufacturers.

Understanding LED Optics

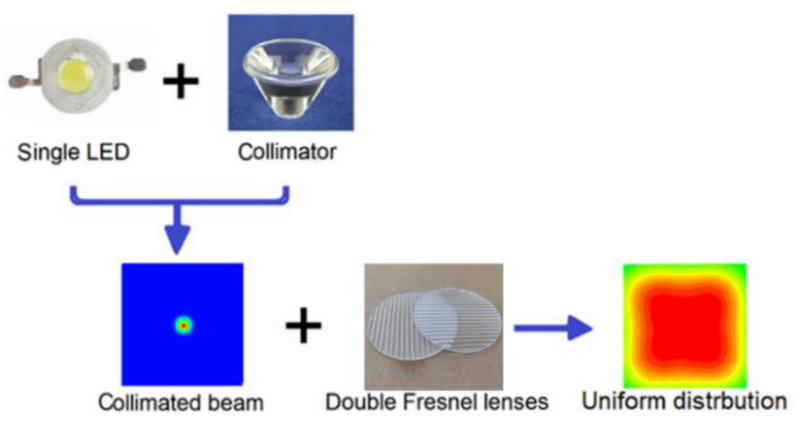

LED optics play a crucial role in the performance of LED lighting systems. They are designed to manipulate and direct light emitted from LEDs, allowing for precise control over light distribution and intensity. The quality of LED optics can significantly affect the efficiency, lumen depreciation, and overall lifespan of lighting fixtures. As such, the role of an LED optics manufacturer is vital in ensuring that these components are designed and produced to meet high standards. The design of LED optics not only influences the aesthetic appeal of lighting fixtures but also impacts energy consumption and the effectiveness of illumination in various environments.

The Importance of Customization

Customization is one of the most significant advantages of modern LED lens manufacturing. Different applications require different light distributions, and custom lenses can be tailored to meet these specific needs. For instance, horticultural lighting may require lenses that maximize light penetration into plant canopies, while automotive lighting may need lenses that enhance visibility and safety. Customization allows manufacturers to address unique challenges posed by specific environments, such as outdoor settings where weather resistance is crucial, or indoor spaces where light quality can affect mood and productivity. This adaptability is essential in a market that increasingly demands personalized solutions.

The Custom LED Lens Development Process

The process of developing custom LED lenses can be broken down into several key stages:

1. Initial Consultation and Design Specification

The first step in the custom LED lens development process is to engage with the client to understand their specific needs. This involves discussing the intended application, desired light distribution patterns, and any other requirements. The manufacturer will gather detailed specifications, which will serve as the foundation for the design process. During this phase, it is essential to establish clear communication channels to ensure that all expectations are aligned. This collaborative approach helps in identifying potential challenges early on and allows for a more streamlined development process.

2. Optical Design and Simulation

Once the specifications are established, the next phase involves optical design and simulation. Using advanced software, designers create models of the lens that predict how light will behave when it passes through. This stage is critical as it allows for adjustments to be made before any physical prototypes are created. The simulation helps in visualizing the light distribution and ensuring that it meets the client's requirements. By employing ray tracing and other optical simulation techniques, designers can analyze various parameters such as beam angle, intensity distribution, and color rendering, which are vital for achieving the desired lighting effects.

3. Prototype Development

After finalizing the optical design, the manufacturer will create a prototype of the lens. This involves using materials such as polycarbonate or silicone, which are commonly used in LED optics due to their excellent optical properties and durability. The prototype is then tested to evaluate its performance against the design specifications. This stage may involve several iterations to refine the lens design further. Prototyping not only allows for practical testing of the design but also provides an opportunity to assess the manufacturability of the lens, ensuring that the final product can be produced efficiently and cost-effectively.

4. Testing and Validation

Testing is a crucial part of the development process. The prototype undergoes rigorous testing to assess its optical performance, durability, and compliance with industry standards. This may include photometric testing to measure light output and distribution, as well as environmental testing to ensure the lens can withstand various conditions. Validation is essential to confirm that the lens performs as intended in real-world applications. This stage often involves collaboration with third-party testing facilities to ensure impartiality and adherence to regulatory standards, which can enhance the credibility of the product.

5. Final Adjustments and Production

Based on the results of the testing phase, final adjustments may be made to the lens design. Once the design is validated, the manufacturer prepares for mass production. This involves setting up the necessary tooling and production processes to ensure that the lenses can be produced efficiently and to the required quality standards. The transition from prototype to production is a critical phase that requires careful planning to avoid any disruptions. Manufacturers often employ lean manufacturing principles to optimize production workflows and minimize waste, ensuring that the final product is both high-quality and cost-effective.

6. Quality Control and Delivery

Quality control is an ongoing process throughout the production phase. Each batch of lenses is inspected to ensure they meet the specified criteria. Once the lenses pass quality checks, they are packaged and delivered to the client, ready for installation in their lighting systems. Effective quality control measures not only ensure product reliability but also enhance customer satisfaction. Manufacturers may implement feedback loops where clients can report performance issues, allowing for continuous improvement in future production runs.

Technologies Used in Custom LED Lens Development

The development of custom LED lenses relies on various advanced technologies:

CAD Software

Computer-Aided Design (CAD) software is essential for creating detailed models of the lenses. This software allows designers to visualize the lens shape and simulate light behavior, making it easier to identify potential issues before prototyping. CAD tools also facilitate collaboration among team members, enabling multiple stakeholders to contribute to the design process. The integration of CAD with simulation software enhances the accuracy of predictions regarding lens performance, ultimately leading to better-designed products.

3D Printing

3D printing technology is increasingly being used in the prototyping phase. It allows for rapid production of lens prototypes, enabling designers to test and iterate designs quickly. This technology can also be used to create complex geometries that may be difficult to achieve with traditional manufacturing methods. The flexibility of 3D printing not only accelerates the prototyping process but also reduces costs associated with tooling and mold creation, making it an attractive option for manufacturers looking to innovate.

Injection Molding

For mass production, injection molding is a common technique used to create LED lenses. This process involves injecting molten material into a mold, allowing for high precision and repeatability in lens production. It is particularly effective for producing large quantities of lenses with consistent quality. The choice of materials for injection molding can significantly impact the optical properties of the lenses, and manufacturers often conduct extensive research to select the best materials for specific applications.

The Role of Collaboration

Collaboration between designers, engineers, and manufacturers is crucial throughout the custom LED lens development process. Effective communication ensures that all parties are aligned on the project goals and can address any challenges that arise. This collaborative approach not only enhances the quality of the final product but also speeds up the development timeline. By fostering a culture of teamwork, manufacturers can leverage diverse expertise and perspectives, leading to more innovative solutions and improved customer satisfaction.

Applications of Custom LED Lenses

Custom LED lenses are used in a wide range of applications, including:

- Architectural Lighting: Enhancing the aesthetic appeal of buildings and public spaces, custom lenses can create dramatic effects and highlight architectural features.

- Automotive Lighting: Improving visibility and safety for drivers and pedestrians, custom lenses can optimize light distribution for headlights, taillights, and interior lighting.

- Horticultural Lighting: Optimizing light for plant growth in indoor farming, custom lenses can be designed to deliver specific wavelengths that promote photosynthesis.

- Industrial Lighting: Providing efficient lighting solutions for warehouses and factories, custom lenses can improve visibility and reduce energy consumption.

These applications demonstrate the versatility of custom LED lenses and their ability to meet the diverse needs of various industries.

Conclusion

The process of custom LED lens development is a complex yet rewarding journey that combines creativity, technology, and collaboration. As the demand for efficient and effective lighting solutions continues to grow, the role of LED optics manufacturers becomes increasingly important. By understanding the intricacies of this process, clients can better appreciate the value of custom LED lenses in enhancing their lighting applications. The future of LED lens development looks promising, with ongoing advancements in materials and manufacturing technologies paving the way for even more innovative solutions.

Frequently Asked Questions

1. What materials are commonly used for custom LED lenses?

- Common materials include polycarbonate, silicone, and acrylic, each chosen for their specific optical properties and durability.

2. How long does the custom LED lens development process take?

- The timeline can vary depending on the complexity of the design and the testing required, but it typically ranges from a few weeks to several months.

3. Can custom LED lenses be designed for specific light distributions?

- Yes, custom lenses can be tailored to achieve specific light distributions based on the application requirements.

4. What is the role of simulation in the lens development process?

- Simulation allows designers to visualize light behavior and make necessary adjustments before creating physical prototypes, saving time and resources.

5. How do manufacturers ensure the quality of custom LED lenses?

- Manufacturers implement rigorous testing and quality control measures throughout the production process to ensure that lenses meet specified standards.